As an advanced electron-optical instrument, the scanning electron microscope will play a big role in improving the technological innovation ability and product quality of the textile industry.

The principle and characteristics of scanning electron microscope

With the continuous emergence of various new textile materials, optical microscopes have become more and more difficult to meet the needs of textile inspection. Scanning electron microscopy has opened up a new way for textile inspection.

Scanning electron microscope (SEM) is an advanced electron-optical instrument that has developed rapidly in recent decades. Currently, the most advanced field emission scanning electron microscope has a resolution of 1nm, and its magnification can range from low to hundreds of thousands of times. In particular, the advent of the low-vacuum scanning electron microscope has made it possible for people to directly observe samples that are non-conductive, easy to degas, and contain water and oil. The imaging principle of the scanning electron microscope is different from that of the optical microscope. It uses some physical signals excited by the finely focused high-voltage electron beam to scan the surface of the material sample to modulate the imaging, which is similar to the imaging method of television photography.

The working principle of the scanning electron microscope is that the electron beam (generally about 50 μm in diameter) emitted by the triode electron gun is converged into an electron beam as small as 5 nm by three electromagnetic lenses (or two electromagnetic lenses) under the action of accelerating voltage. The probe, under the action of the scanning coil on the upper part of the final lens, makes the electronic probe do a raster scan on the surface of the sample (the number of raster lines depends on the line scan and frame scan speed).

As a result of the interaction between high-energy electrons and matter, various information such as secondary electrons, backscattered electrons, Auger electrons and X-rays are generated on the sample. The electronic information is amplified and converted into a voltage signal, and finally sent to the grid of the picture tube to modulate the brightness of the picture tube.

The electron beam in the picture tube also performs raster scanning on the fluorescent screen. This scanning movement is strictly synchronized with the scanning movement of the electron beam on the surface of the sample, so that a scanning electron image with a contrast corresponding to the intensity of the received signal is obtained. The image reflects The morphology of the sample surface.

9 Features of Scanning Electron Microscope

(1) It is possible to directly observe the original surface of the large-sized sample;

(2) The degree of freedom of the sample in the sample chamber is very large;

(3) The observation field is large;

(4) The image has a large depth of field and a strong three-dimensional effect;

(5) High-resolution images can be obtained for thick samples;

(6) The radiation has little pollution on the surface of the sample;

(7) Capable of dynamic observation (such as dynamic stretching, compression, bending, heating and cooling, etc.);

(8) Able to obtain multi-faceted information corresponding to the shape;

(9) Expand additional functions without sacrificing the characteristics of the scanning electron microscope, such as micro-region composition and crystallographic analysis.

Fiber is a substance composed of continuous or discontinuous filaments, which can be divided into natural fibers and chemical fibers. These two types of fibers are widely used in many fields such as textiles, military industry, environmental protection, and biomedicine. Since the physical morphology and chemical structure of the surface of the fiber material are the main factors determining the performance of the material, it is usually necessary to use relevant microscopic equipment to observe the microscopic morphology of the fiber surface and other information, so as to judge the basic performance of the fiber material. As a conventional microscopic characterization equipment, the scanning electron microscope has the advantages of large magnification, high resolution, large depth of field, clear image, and strong stereoscopic effect. When the scanning electron microscope is equipped with an energy spectrometer, it can also be used to characterize fiber composition information , which plays an irreplaceable role in the research and development and production of fibers.

With the continuous improvement of people’s quality of life, people not only pay attention to basic capabilities such as cold protection and warmth, but also pursue various functions when purchasing clothes. For example, common sportswear needs to have good waterproof and moisture-permeable performance, that is, to prevent liquid water from contacting the human body while ventilating and perspiring.

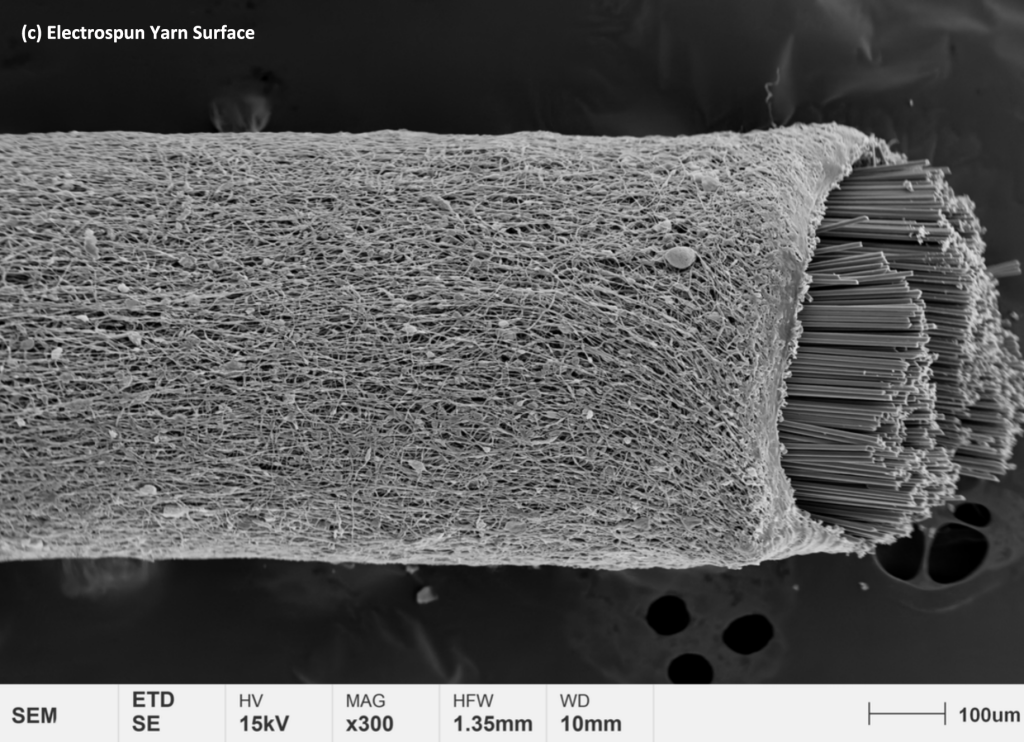

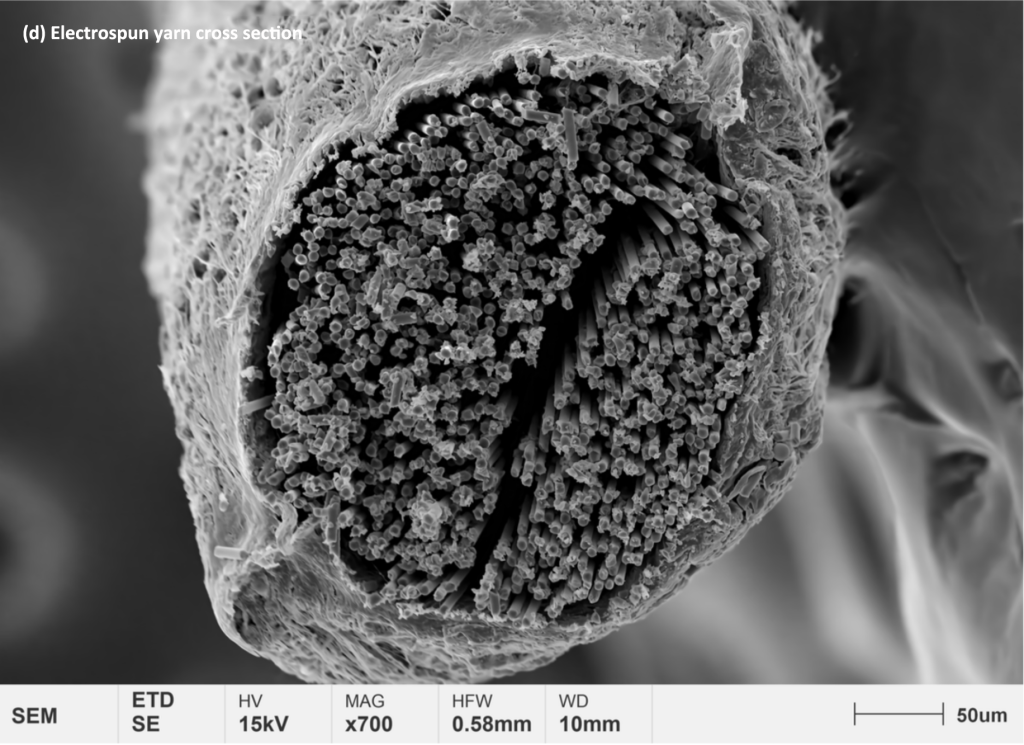

At present, the main research direction of waterproof and moisture-permeable fabrics is to combine functional films with ordinary fabrics to achieve waterproof and moisture-permeable effects. According to research, waterproof and moisture-permeable fabrics often use electrospinning technology to combine nanofiber membranes with traditional fabrics to form laminated fabrics to achieve waterproof and moisture-permeable purposes. Electrospun nanofibrous membranes under different conditions have different pore structures and specific surface areas, so scanning electron microscopes are often used to detect nanofibrous membranes prepared under various conditions, so as to select the best manufacturing process to make them have higher Porosity and large specific surface area.

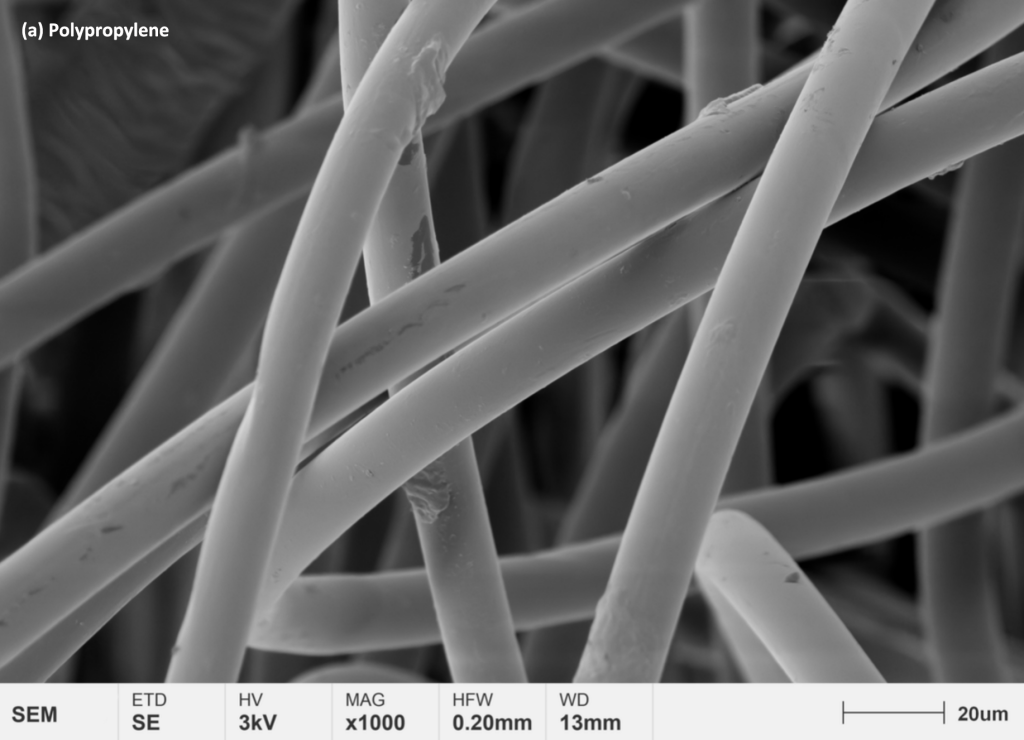

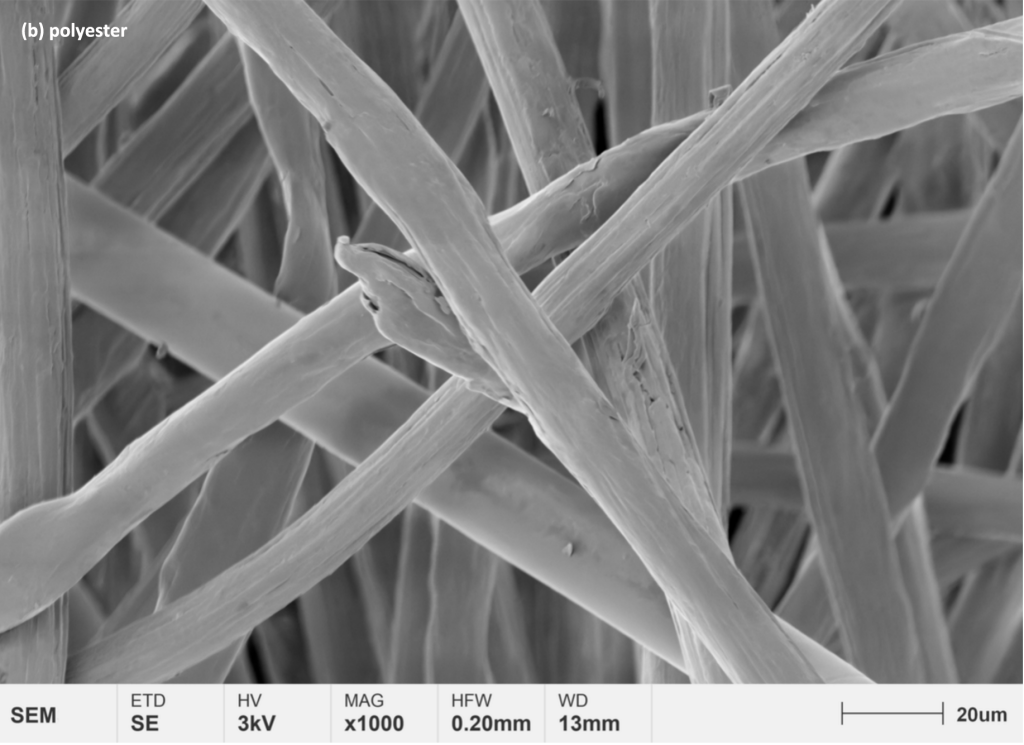

Researchers used Guoyi quantum tungsten filament scanning electron microscope SEM3200 to observe and study textile fibers such as polyester, polypropylene and electrospun nanofibers. With optical navigation and perfect automatic functions, we can quickly and clearly observe the microscopic morphology of these fibers.

From the electron microscope pictures of polypropylene and polyester, it can be seen intuitively that the fiber surface of polypropylene is smoother than that of polyester, and the fiber size is more uniform.

From the electrospinning line, it can be seen that the carbon fiber is wrapped by spinning, and there is no obvious defect, which indirectly verifies the reliability of the spinning process.

Future Development of Scanning Electron Microscope and Its Application Prospect in Textile Materials Research

As a commonly used microscopic analysis tool, scanning electron microscopy can observe various types of fiber materials in various forms, and conduct research on fiber material identification, quality monitoring, failure analysis, and surface modification. With the continuous advancement of the high-quality development of the textile industry, scanning electron microscopes, a high-end scientific instrument, are also expected to assist manufacturers in the development of new fiber materials and continue to escort our high-quality life.

The future development of SEM is mainly in:

The combination of two types of high-resolution and analytical electron microscopes, while realizing computer control, has developed into a multi-functional high-resolution analytical electron microscope. It satisfies the needs of ultra-light elements, low content, high-speed qualitative and quantitative routine analysis of a large number of multi-element samples to the greatest extent. Improve the resolving power of the conventional accelerating voltage, improve the low-voltage performance, and reduce or even eliminate the damage and damage to the sample. No need to spray the conductive layer or freeze-dry first, keep the sample as it is for observation. Develop a new comprehensive electronic microscope accessory equipment in order to obtain more sample information.