What is lithium battery negative electrode material

The negative electrode material of lithium battery is an important part of the carbon battery, which directly affects the performance and stability of the lithium battery.

The negative electrode materials of lithium batteries usually include graphite, silicon-based materials, and metallic lithium. Among them, graphite is currently the most widely used negative electrode material, and its main component is carbon.

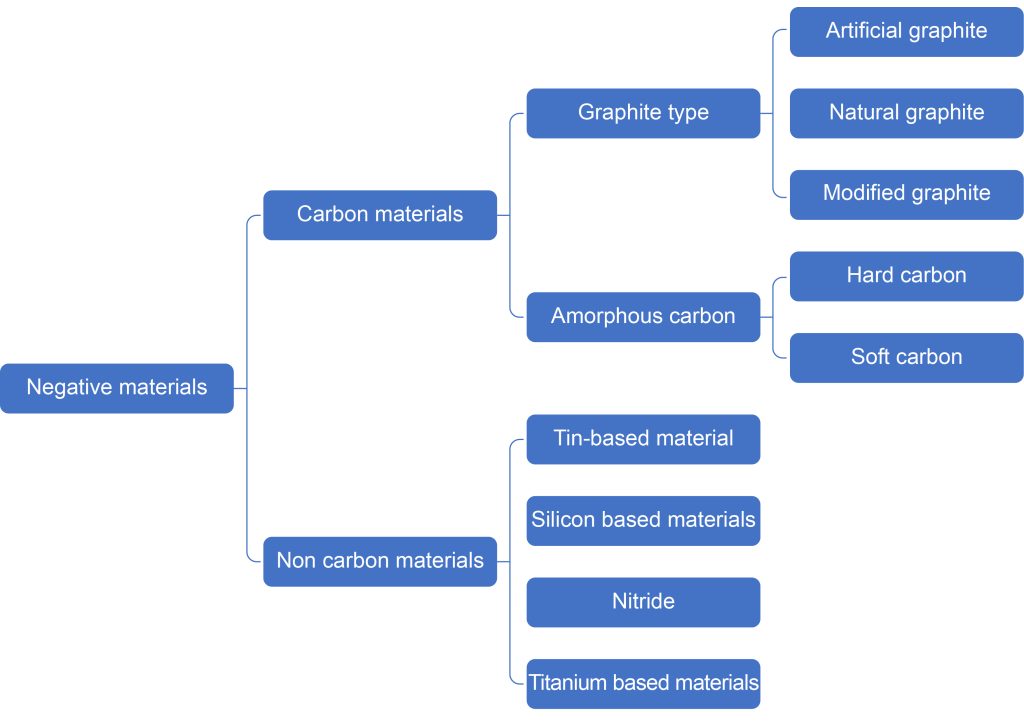

Lithium battery anode materials are divided into two major categories: the first category is carbon materials, including graphitized carbon materials and amorphous carbon materials; the second category is non-carbon materials, mainly including silicon-based materials, tin-based materials, transition metal oxides, Metal nitrides, and other alloy anode materials, etc.

The negative electrode of a lithium-ion battery is made by mixing the negative active material carbon material or non-carbon material, binder, and additives to make a paste-like adhesive, which is evenly applied on both sides of the copper foil, dried, and rolled. The key to the successful production of lithium-ion batteries lies in the ability to prepare negative electrode materials that can reversibly deintercalate lithium ions.

Sources and characteristics of negative electrode material raw materials

Carbon material anode is a general term, generally divided into five categories: graphite, hard carbon, soft carbon, carbon nanotubes, and graphene. Graphite is further divided into natural graphite, artificial graphite, and mesophase carbon microspheres.

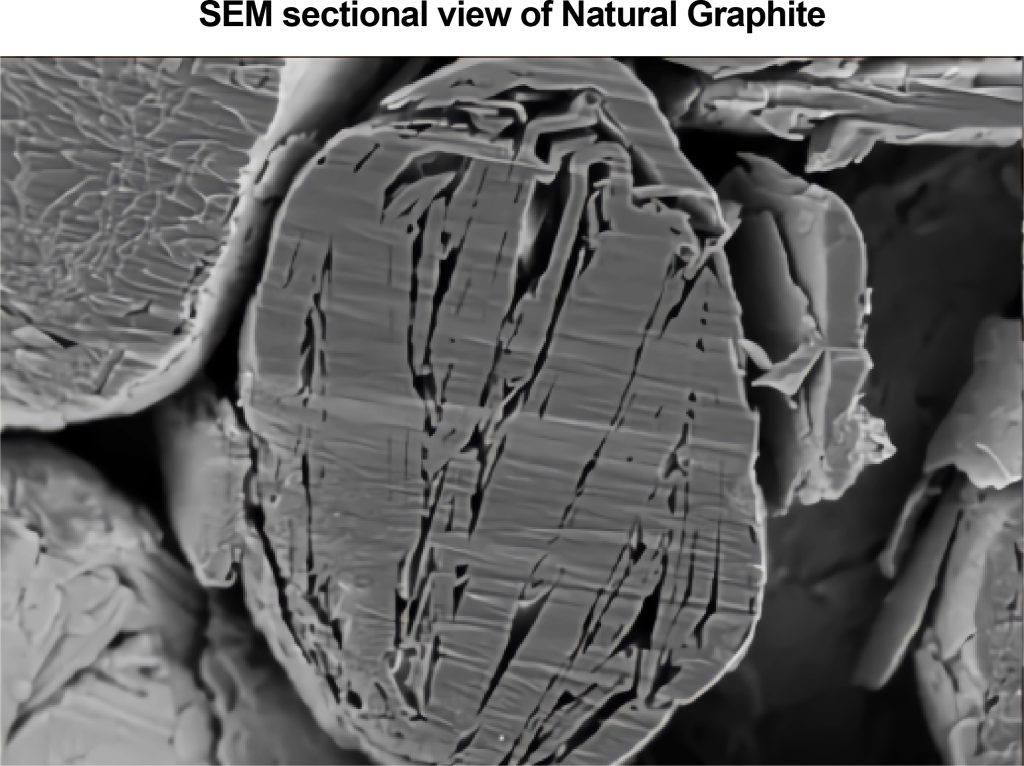

Natural graphite negative electrode

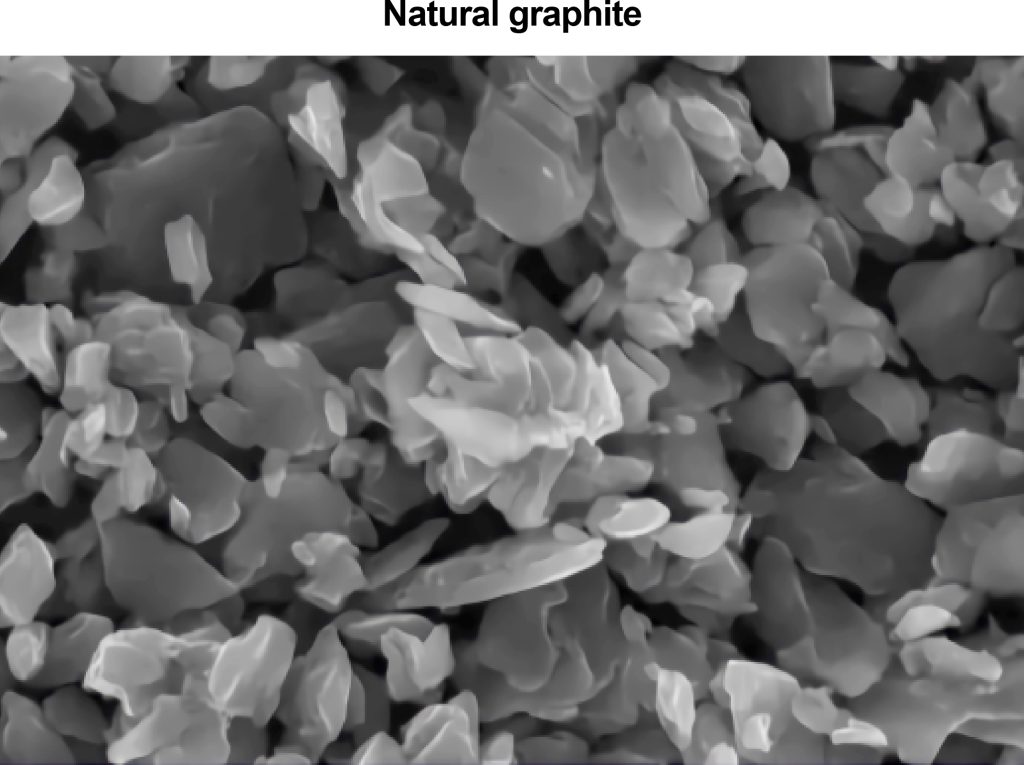

Natural graphite negative electrodes are processed from natural graphite. Domestic graphite resource reserves and output are abundant, and the mining cost is low. Natural graphite has a relatively complete graphite sheet structure and a high degree of graphitization, which is suitable for the deintercalation and shuttle of lithium ions, and. The disadvantage is that natural graphite has poor cycle performance without modification.

Artificial graphite negative electrode

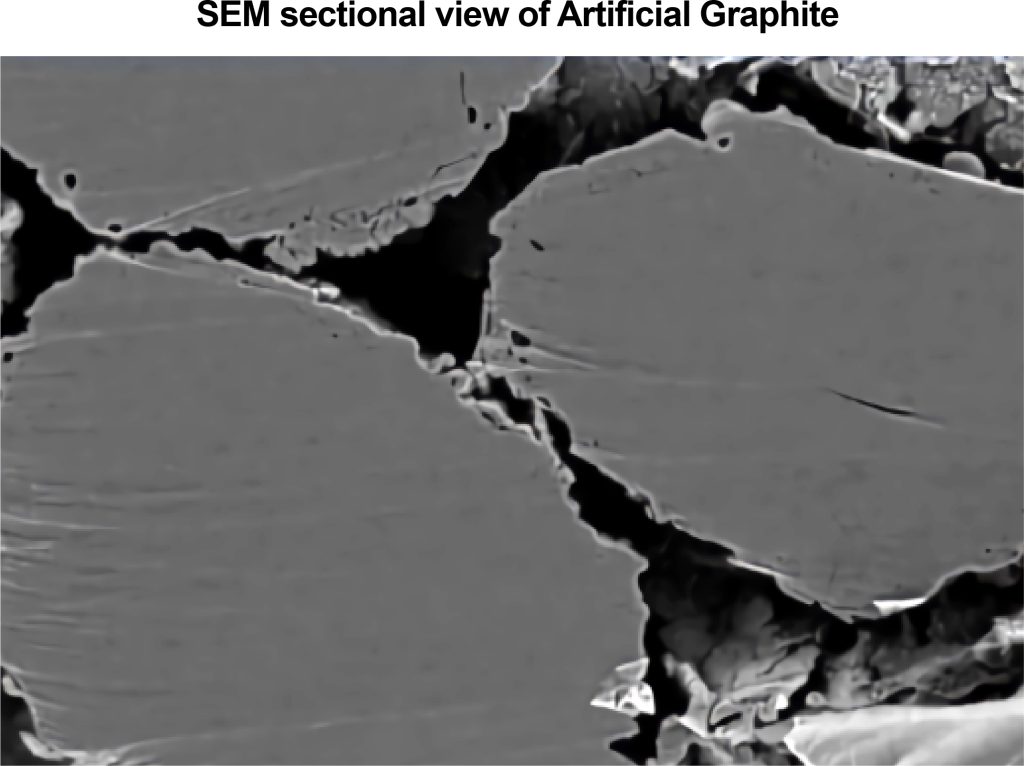

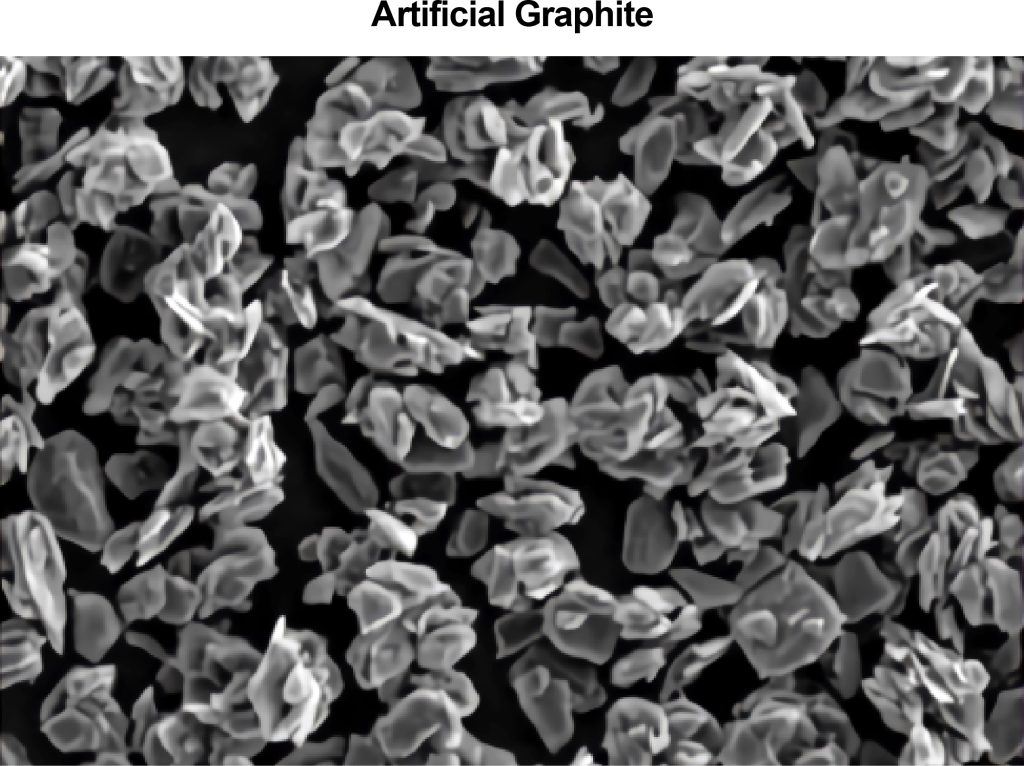

Artificial graphite anode is processed from carbon materials. It is made by subjecting soft carbon materials that are easy to graphitize to graphitization at temperatures above 2500°C. At this time, the secondary particles inside the carbon material are arranged in a random manner and there is a large number of pore structures. This is conducive to the penetration of electrolytes and the deintercalation and shuttle of lithium ions in the negative electrode. Therefore, the artificial graphite negative electrode material can improve and increase the rapid charge and discharge speed and number of lithium batteries.

Soft carbon

Amorphous carbon with a graphitized structure can be processed under high-temperature conditions (>2500°C). The outstanding advantages of soft carbon materials are high reversible specific capacity, generally greater than 300mAh/g, and good compatibility with organic solvents. Therefore, the lithium battery has good cycle stability and is more suitable for charging and discharging lithium batteries with high current density.

Carbon nanotubes

Anode materials with excellent performance should have high specific energy, low electrode potential relative to lithium electrodes, good reversible performance of charge and discharge reactions, and good compatibility with the electrolyte. Natural graphite has higher capacity and simple process, lower cost, but poor cycle performance, while artificial graphite has a slightly more complex process and higher cost, but has better cycle and safety performance. Mesophase carbon microsphere graphite has a higher rate of performance than natural stone. Ink and artificial graphite, so it has good thermal stability and chemical stability, but its production process is complicated and the cost is high. The capacity ratio of silicon-carbon composite materials is much higher than that of graphite-based anodes. They are environmentally friendly and have abundant domestic reserves. However, because lithium is easily embedded in the silicon unit cell during the reaction process, the expansion capacity of the material decreases rapidly, so the cycle life is low. Considering both cost and performance, natural graphite still occupies the mainstream position in the field of power batteries.

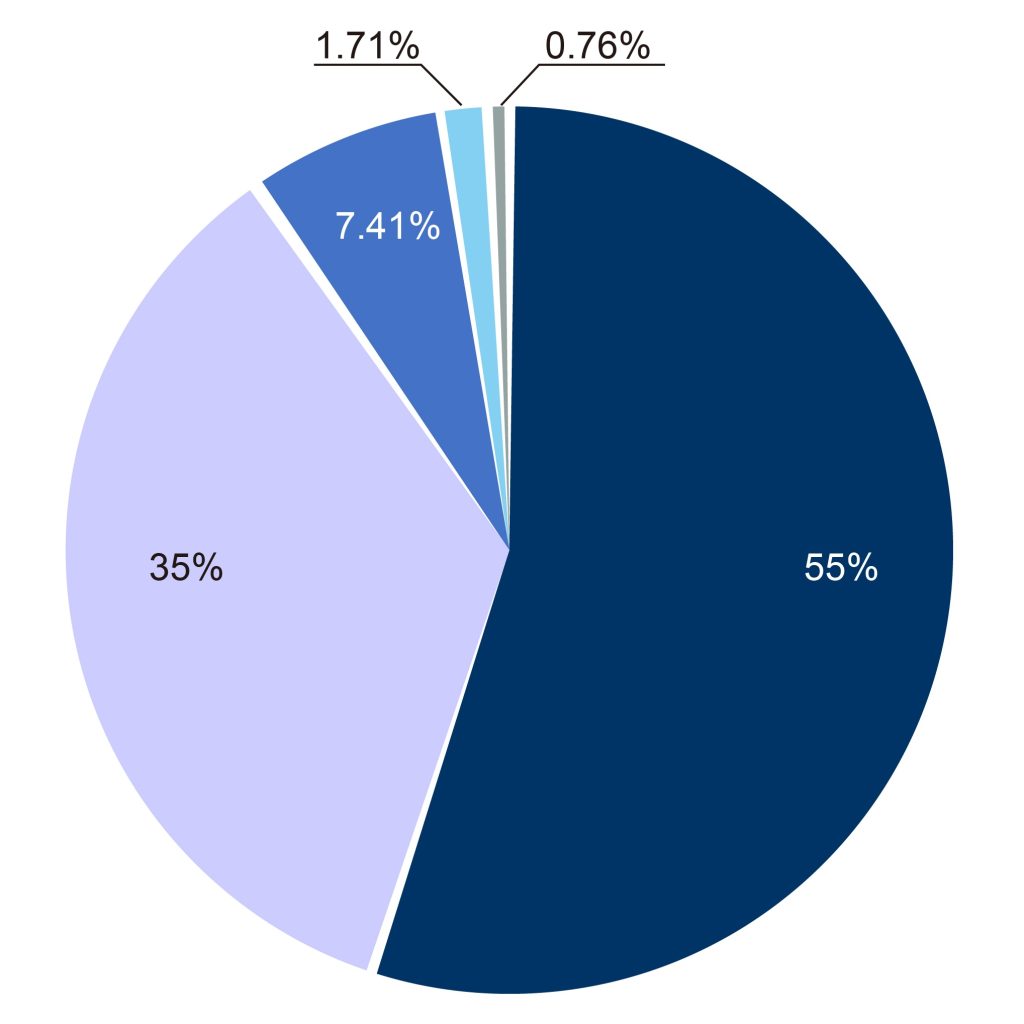

Judging from the proportion of global anode material shipments in 2016, natural graphite accounted for 55%, artificial graphite accounted for 35%, and mesophase carbon microspheres accounted for 7.4%. Overall, carbon materials are the leading anode materials. Mainstream, accounting for more than 90% of the total. Since carbon-based anode materials have the best overall performance in terms of specific capacity, cycle life, and cost, and my country is also the country with the richest carbon resources in the world (accounting for 70% of the world), carbon-based anode materials currently have the highest overall performance.

Future development prospects of anode materials

The technical interpretation of negative electrode materials in the later period can be roughly summarized as the following three points: First, graphite negative electrode materials, especially artificial graphite, will be the mainstream technology route in the next 2-3 years. Second, modifications such as oxidation, coating of polymers, coating of carbon materials, and metal oxidation of natural graphite materials can increase their capacity. At the same time, the cost is relatively low, and it is also the main breakthrough direction for negative electrode materials in the future. Third, tin-based and silicon-based materials have high specific capacity and safety, but poor cycle stability, and the preparation process is complex and costly. The focus of the later breakthroughs for this type of materials will be to develop simple and easy preparation processes while improving their stability. sex.

Application of optical microscope in negative electrode materials

The source of artificial graphite as anode material: coal-based needle coke, petroleum-based needle coke, and petroleum coke. Among them, high-end anode materials use needle coke as raw materials, and low-end anode materials use petroleum coke (except needle coke) as raw materials, and asphalt exists as a binder, except for mesocarbon microspheres (MCMB).

Petroleum coke products can be divided into four types: needle Coke, sponge Coke, pellet Coke and powder Coke

Needle coke has the advantages of small resistivity, small thermal expansion coefficient, strong impact resistance, high mechanical strength, good oxidation resistance, and low consumption.

Pitch needle coke is different from ordinary pitch coke in appearance. Ordinary pitch coke has the shape of ordinary coke, with large pores and a porosity of up to 50%. Asphalt needle coke is a needle-like crystal with a streamlined fiber structure. It is characterized by a small expansion coefficient, small specific resistance, high apparent density (low porosity), low reactivity, and easy graphitization.

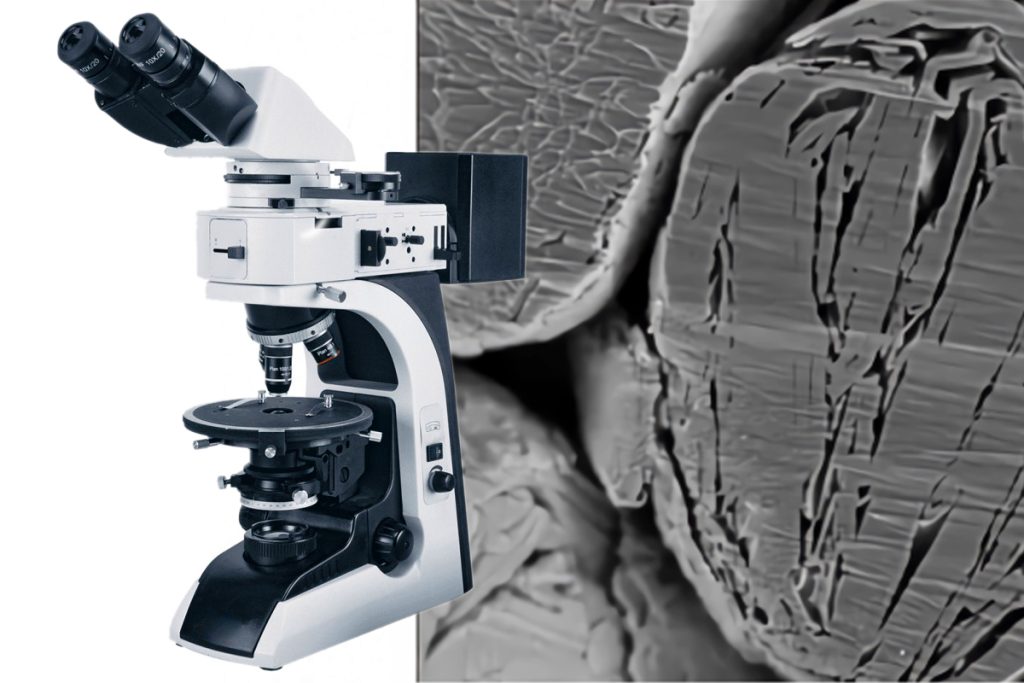

As shown below: Artificial graphite is increasingly used as anode material for lithium batteries because of its relatively uniform particle size and good stability.

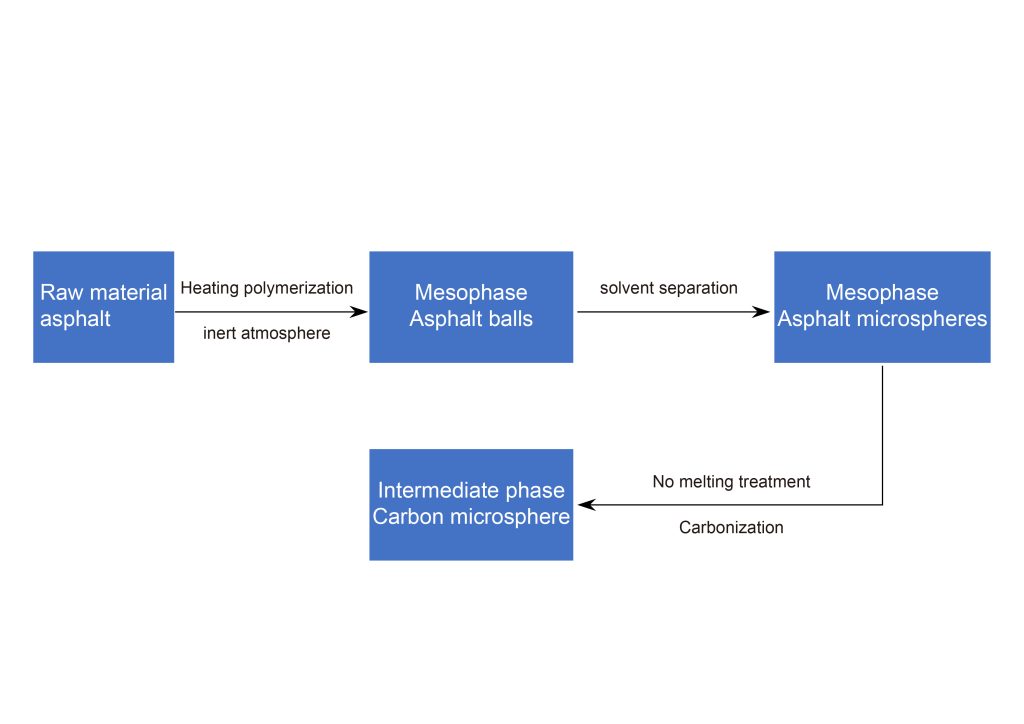

The process of mesophase carbon microspheres is as shown below:

Polarizing microscope Scope5 pol, lab5 pol

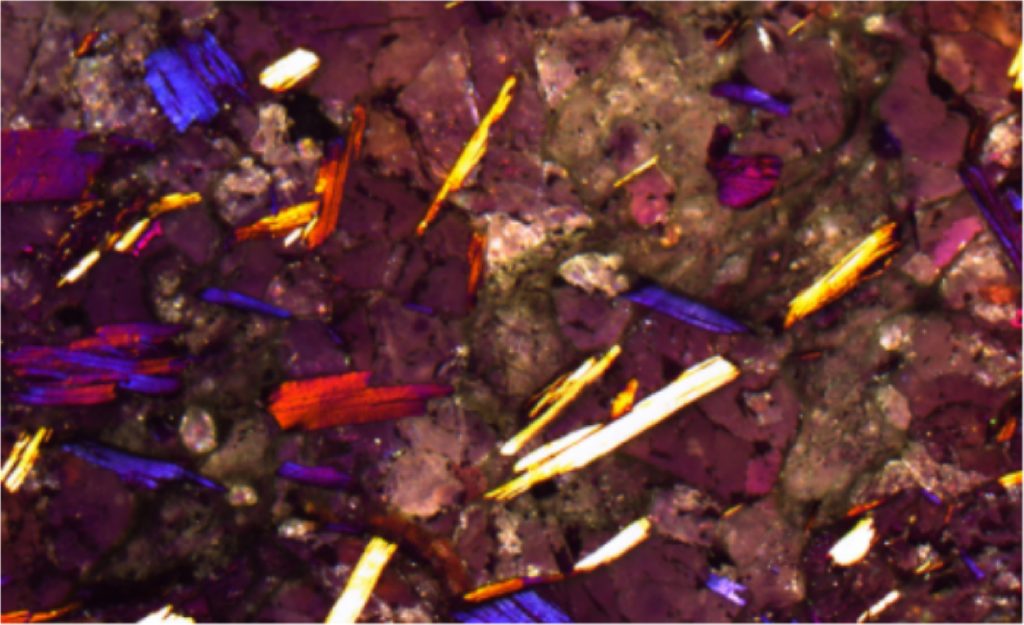

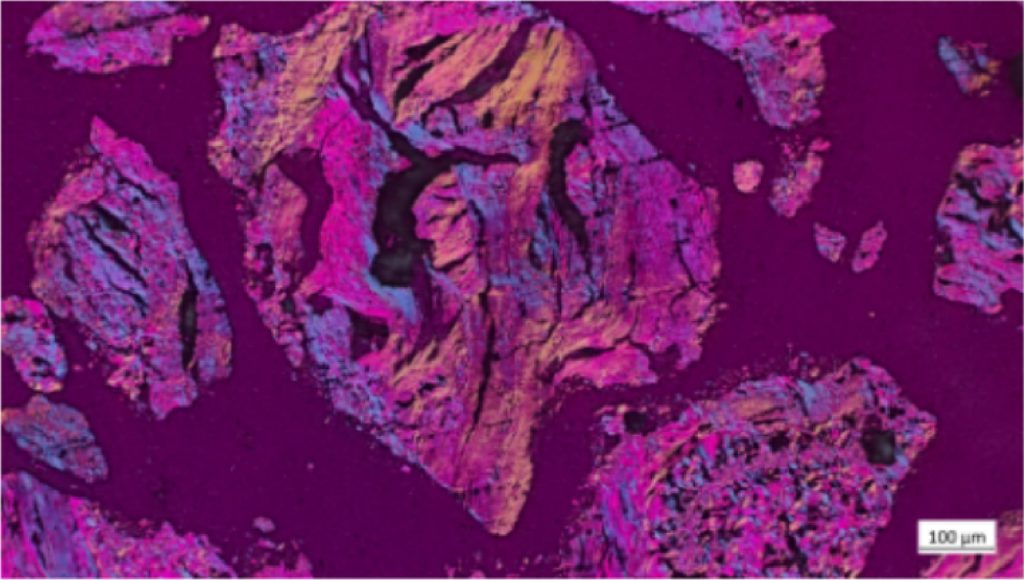

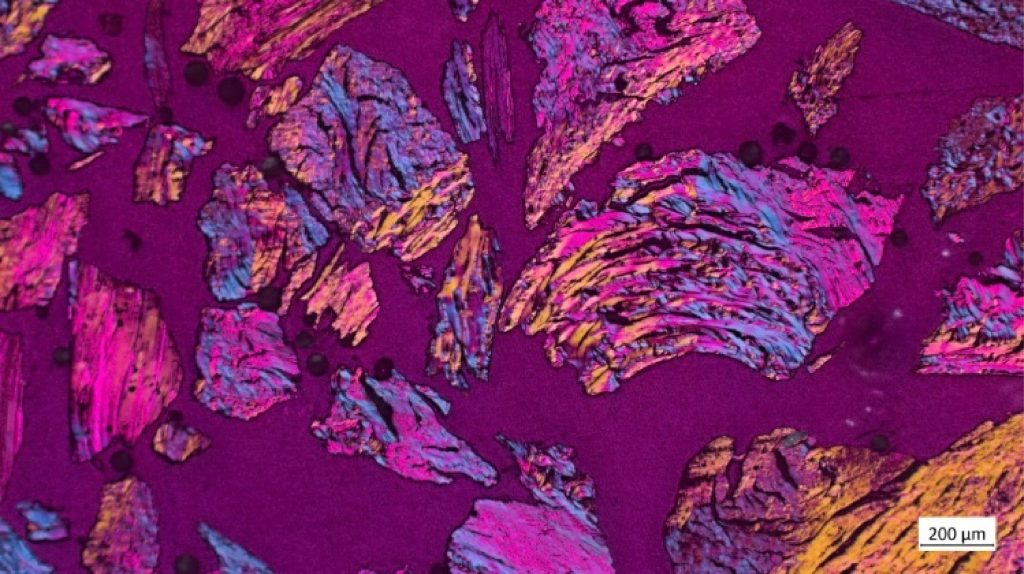

1) The following pictures are natural graphite ores (photographed using a 102 color polarized ruler)

50X (with color polarization compensation)

50X (with color polarization compensation)

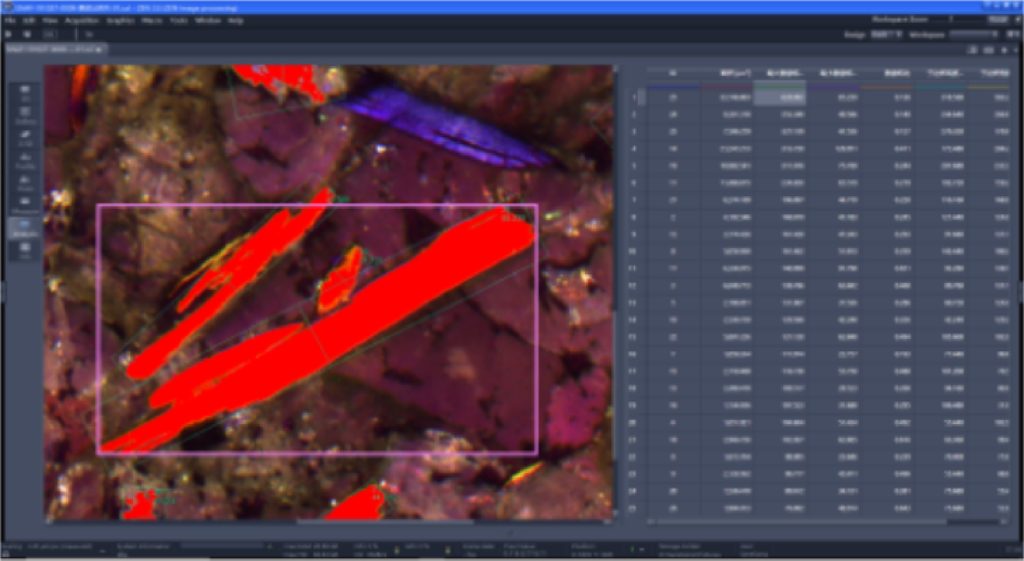

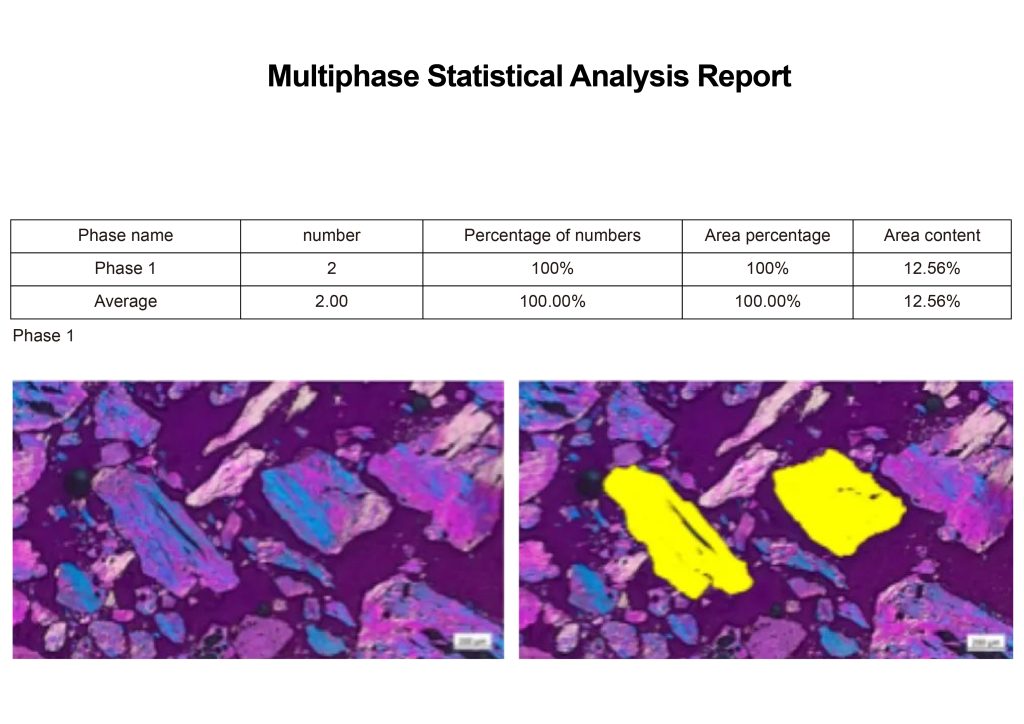

Use Zeiss special analysis software to analyze the distribution of graphite with the same orientation

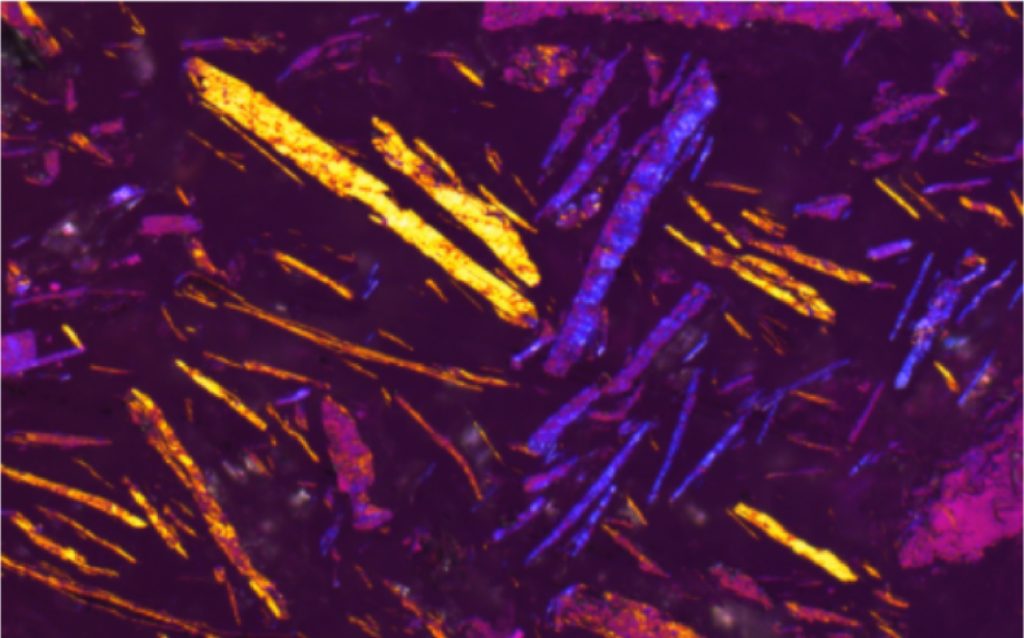

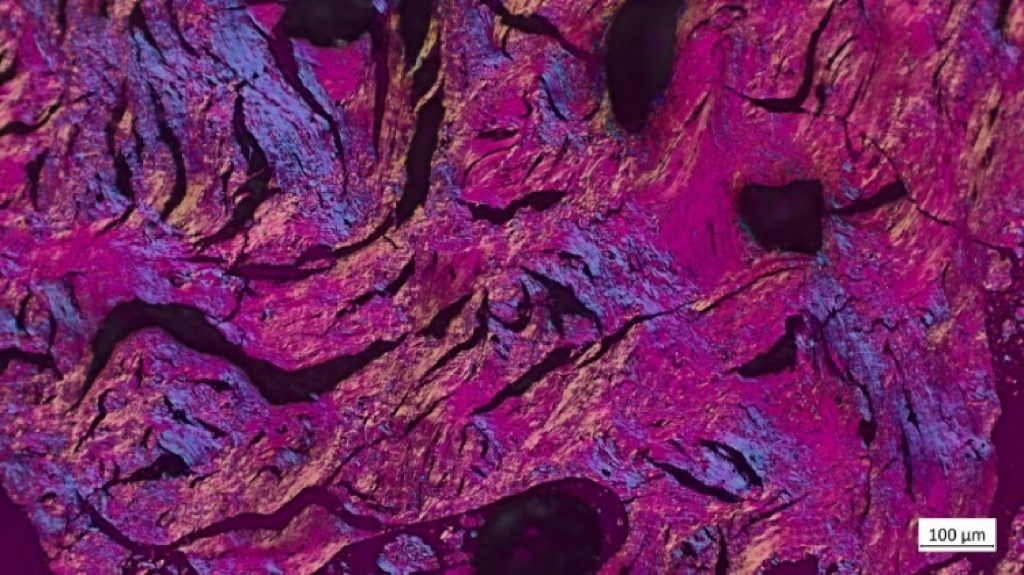

2) As shown below, asphalt focus (photographed using a 102 color polarized slide ruler)

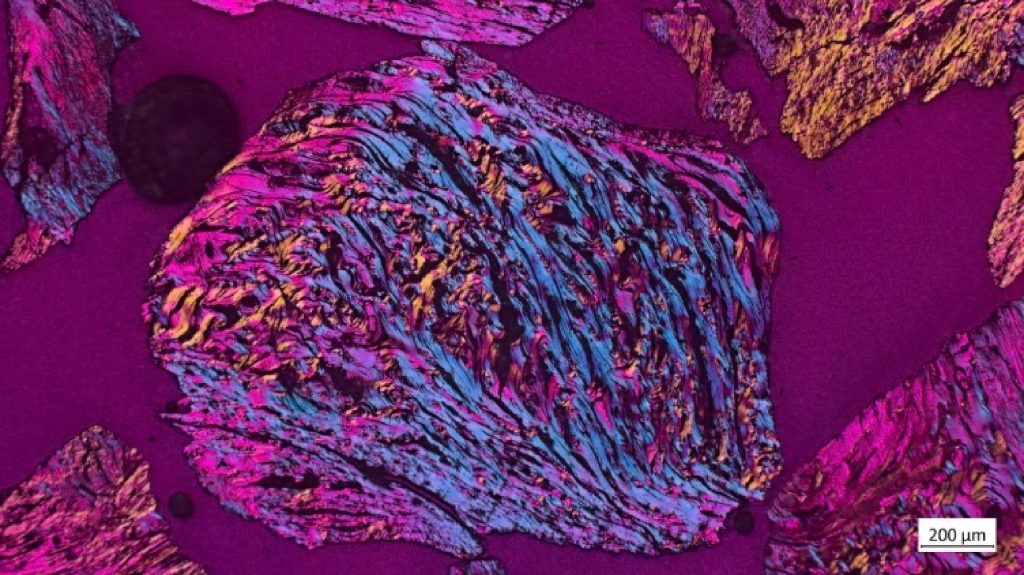

100X (with color polarization compensation)

100X (with color polarization compensation)

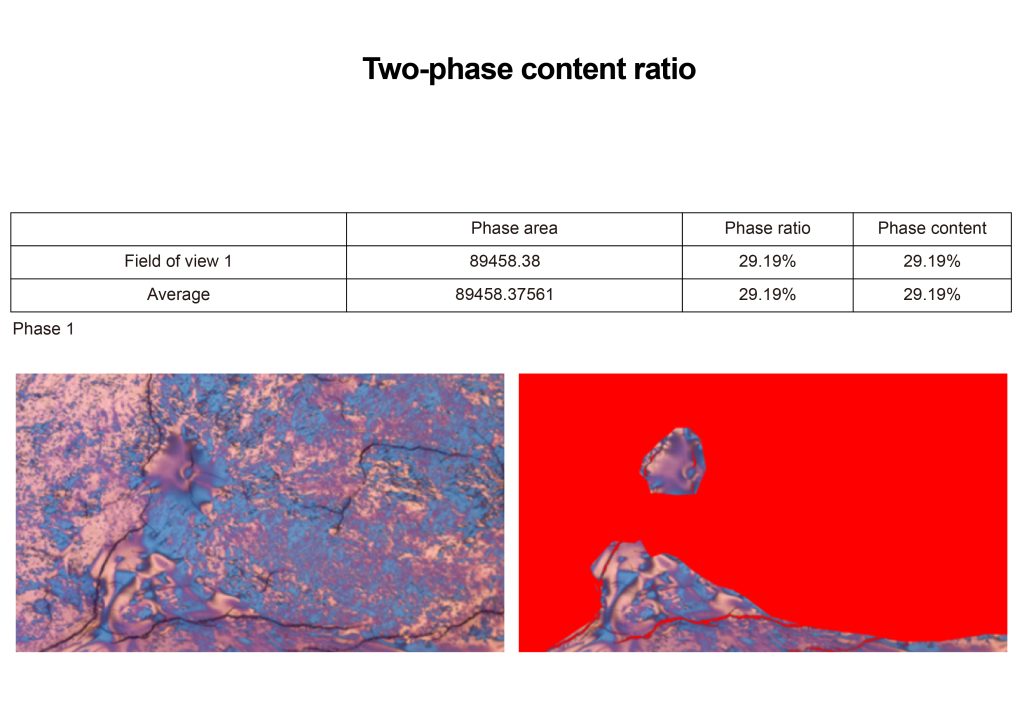

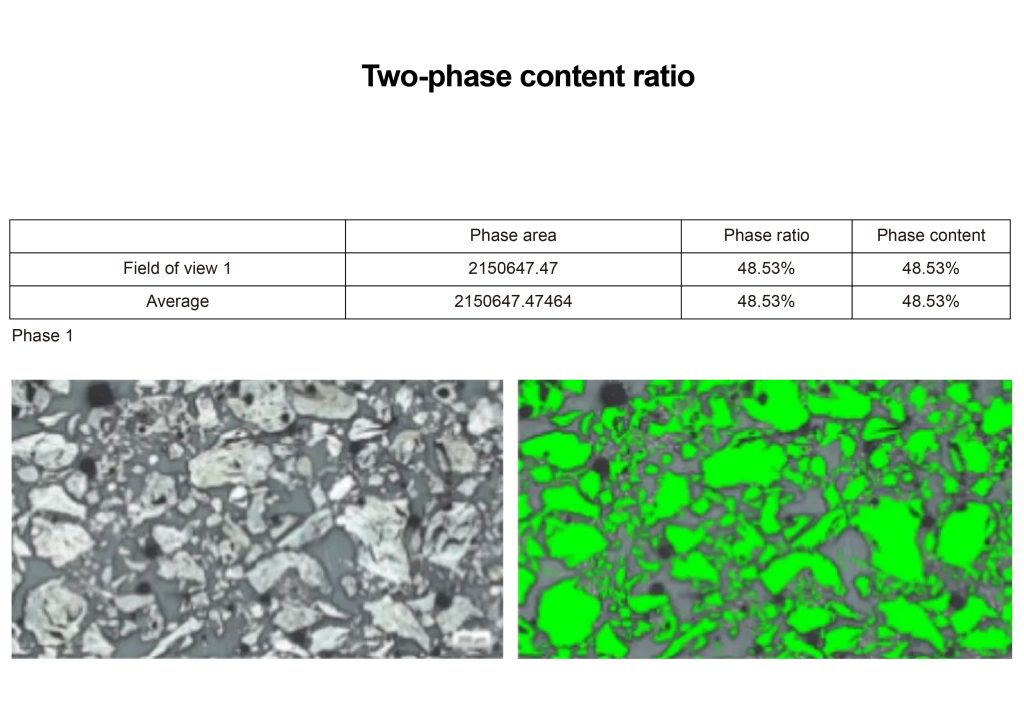

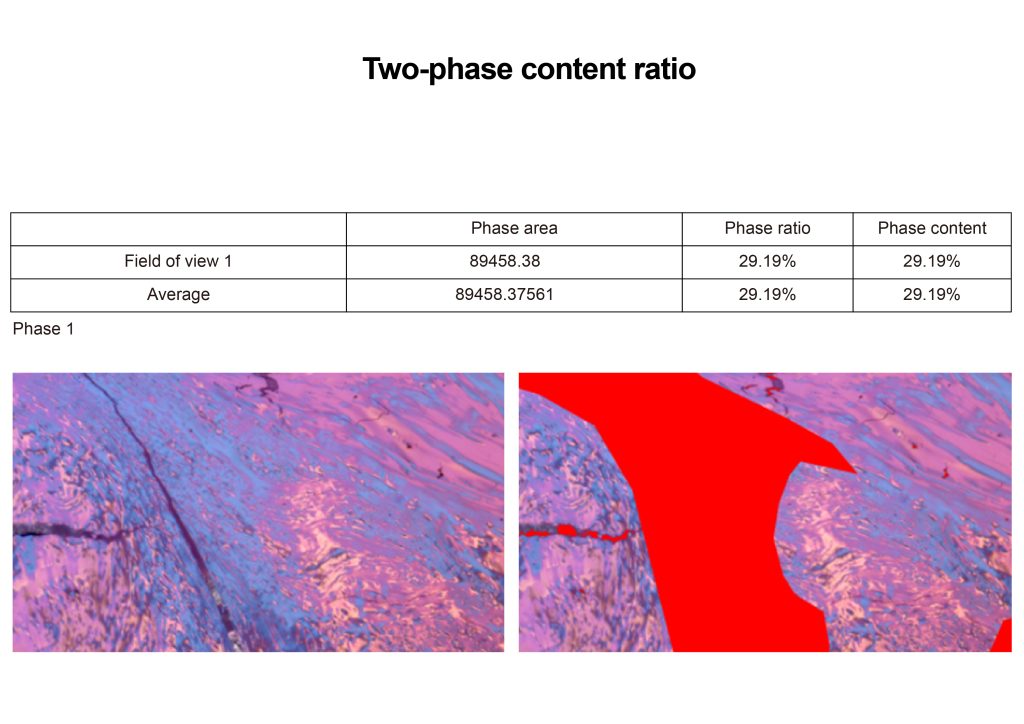

The following figure shows the content measurement of pitch coke (extraction and analysis by Zeiss special software)

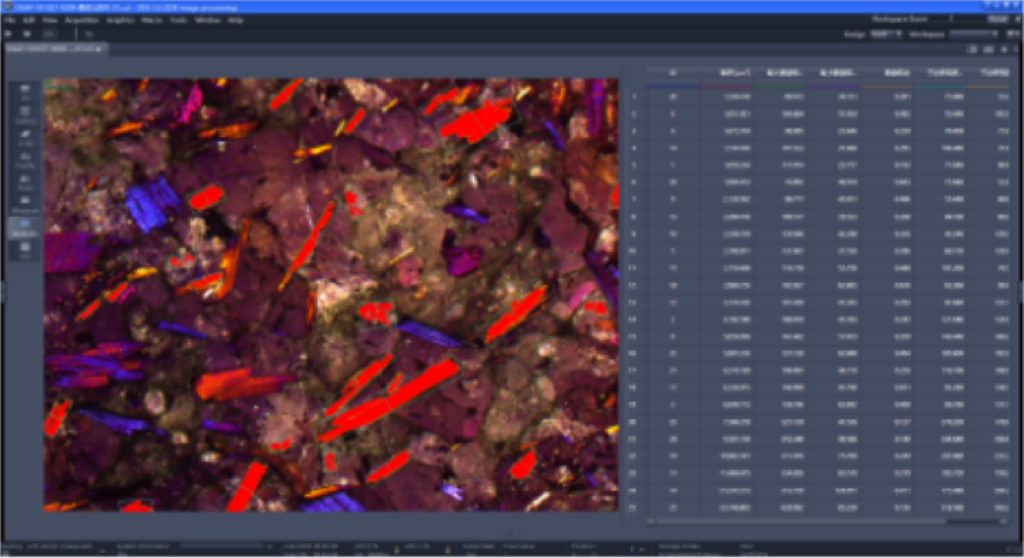

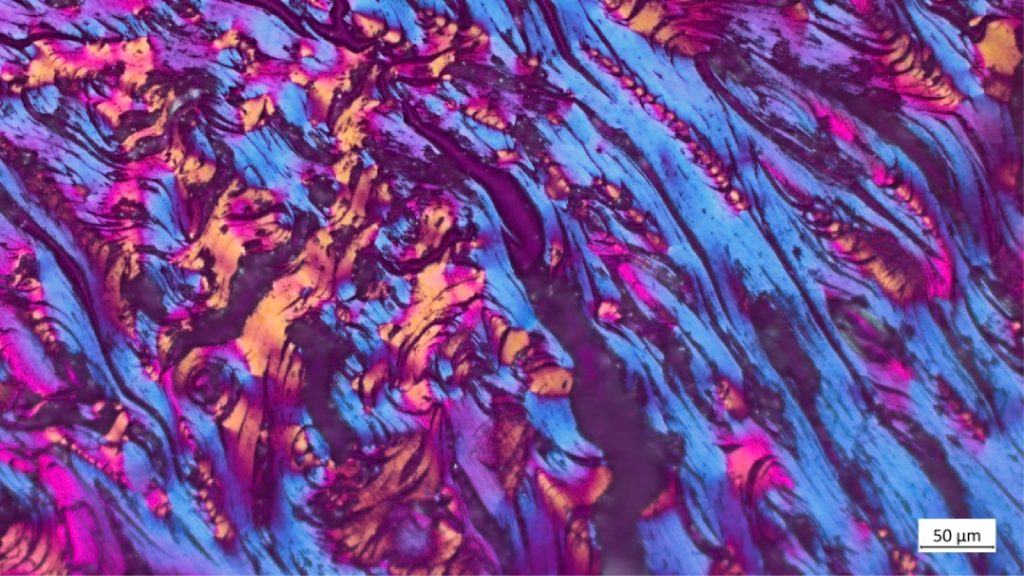

3) As shown below: Needle focus (use 102 color polarized ruler)

50X (color polarized)

50X (color polarized)

200X (color polarized mode)

Analysis of petroleum coke needle coke content results

Analysis of needle coke mosaic tissue content results