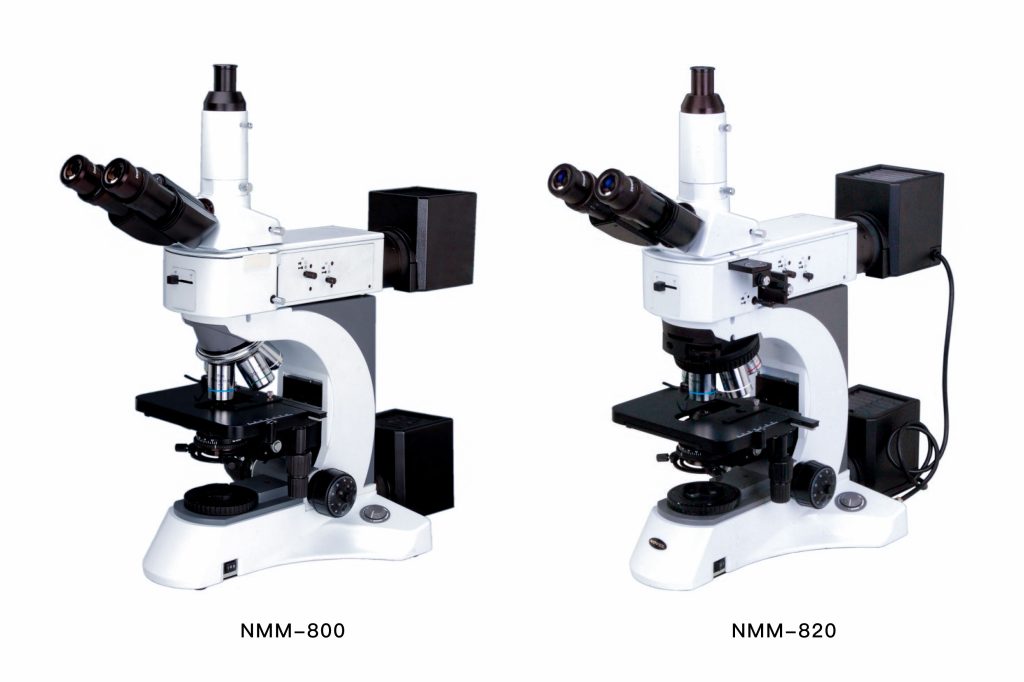

Performance of NMM-800/820 series metallographic microscopes

- Laboratory metallurgical microscope, including bright field, dark field, and polarization observation system.

- Powerful transmitted and reflected system with Kohler illumination.

- Ideal instrument for industry inspection and science research.

Technical parameters of NMM-800/820 series metallographic microscopes

| NMM-800RF | NMM-800TRF | NMM-820RF | NMM-820TRF | |||

| Optical System | Infinite optical system | ● | ● | ● | ● | |

| Eyepiece | ExtrawidefieldeyepieceEW10X/22,Mirror tube Φ30 | ● | ● | ● | ● | |

| Infinite Plan Achromatic Objective | 5X/0.12/∞/-(BF) | WD 15.5mm | ● | ● | ||

| 10X/0.25/∞/-(BF/DF) | WD 10.0mm | ● | ● | ● | ● | |

| 20X/0.4/∞/0(BF/DF) | WD 4.30mm | ● | ● | ● | ● | |

| 50X/0.75/∞/0(BF) | WD 0.32mm | ● | ● | |||

| 100X/0.8/∞/0(BF) | WD 2mm | ● | ● | |||

| 40X/0.65/∞/0.17 | WD 0.54mm | ● | ● | |||

| 100X/1.25/∞/0.17 | WD 0.13mm | ● | ● | |||

| 2.5X/0.08/∞/-(BF) | WD 11.7mm | ○ | ○ | ○ | ○ | |

| 2.5X/0.08/∞/-(BF) | WD 10.7mm(λ玻片) | ○ | ○ | ○ | ○ | |

| 5X/0.12/∞/-(BF/DF) | WD 12mm | ○ | ○ | ● | ● | |

| 40X/0.6/∞/0(BF/DF) | WD 2.90mm | ○ | ○ | ○ | ○ | |

| 50X/0.75/∞/0(BF/DF) | WD 0.32mm | ○ | ○ | ● | ● | |

| 100X/0.8/∞/0(BF/DF) | WD 2mm | ○ | ○ | ● | ● | |

| Differential Interference | 20X, 100X | ○ | ○ | |||

| Maximum Sample Height | 30mm | ● | ● | |||

| 50mm | ● | ● | ||||

| Viewing Head | ExtrawidefieldeyepieceEW10X/22, Mirror tube Φ30 | ● | ● | ● | ● | |

| Incident Light | 24V/100W Halogen light, lightness adjustable | ● | ● | ● | ● | |

| Siedentopf trinocular viewing head. inclined at 30°, interpupillary 48mm-75mm | ● | ● | ● | ● | ||

| Polarizer and analyzer | ○ | ○ | ○ | ○ | ||

| 24V/100W Halogen light and aspherical condenser | ○ | ○ | ○ | ○ | ||

| Blue, Green, Yellow and Ground glass | ● | ● | ● | ● | ||

| Transmitted Light | An integrated device for polarizer and analyzer | ● | ● | |||

| An integrated device for polarizer and analyzer | ● | ● | ||||

| Blue filter | ● | ● | ||||

| Filter | ND25, ND6 | ○ | ○ | ○ | ○ | |

| Focusing | Coaxial coarse and fine adjustment, fine division 1μm, moving range 30mm | ● | ● | ● | ● | |

| Nosepiece | Backward quintuple nosepiece | ● | ● | ● | ● | |

| Stage | Non-porous double layer mechanical stage 186X138mm/74mmX50mm | ● | ● | |||

| Double layer mechanical stage 186X138mm/74mmX50mm | ● | ● | ||||

| Glass specimen preparation plate | ○ | ○ | ○ | ○ | ||

| Specimen preparation plate | ● | ● | ||||

| Slide glass | ● | ● | ||||

| Specimen Presser | ○ | ○ | ○ | ○ | ||

| Photo Attachment | ○ | ○ | ○ | ○ | ||

| Video Attachment | C Mount 1X, 0.5X | ○ | ○ | ○ | ○ | |

Definition of metallographic microscope

The metallographic microscope system organically combines a traditional optical microscope with a computer (digital camera) through photoelectric conversion. Not only can microscopic observations be made on the eyepiece, but also real-time dynamic images can be observed on the computer (digital camera) display screen. , computer-based metallographic microscope, and can edit, save, and print the required pictures.

A metallographic microscope is mainly composed of an optical system and an illumination system. The optical system includes eyepieces, relay systems, and objectives.

Typical applications include grain size, inclusion counting, layer thickness assessment and phase determination. Some models have special facilities, such as darkfield and DIC, that provide improved observation techniques for certain classes of specimens.

Metallographic microscopes all have polarized light capabilities, a range of filters, and camera ports for photography and image analysis; some upright models have both incident and transmitted light for use with more transparent materials.