An acoustic microscope is a microscopic device that uses sound waves as a means of detection. Acoustic microscopes that use sound waves in the ultrasonic segment as probe waves are also called ultrasonic microscopes.

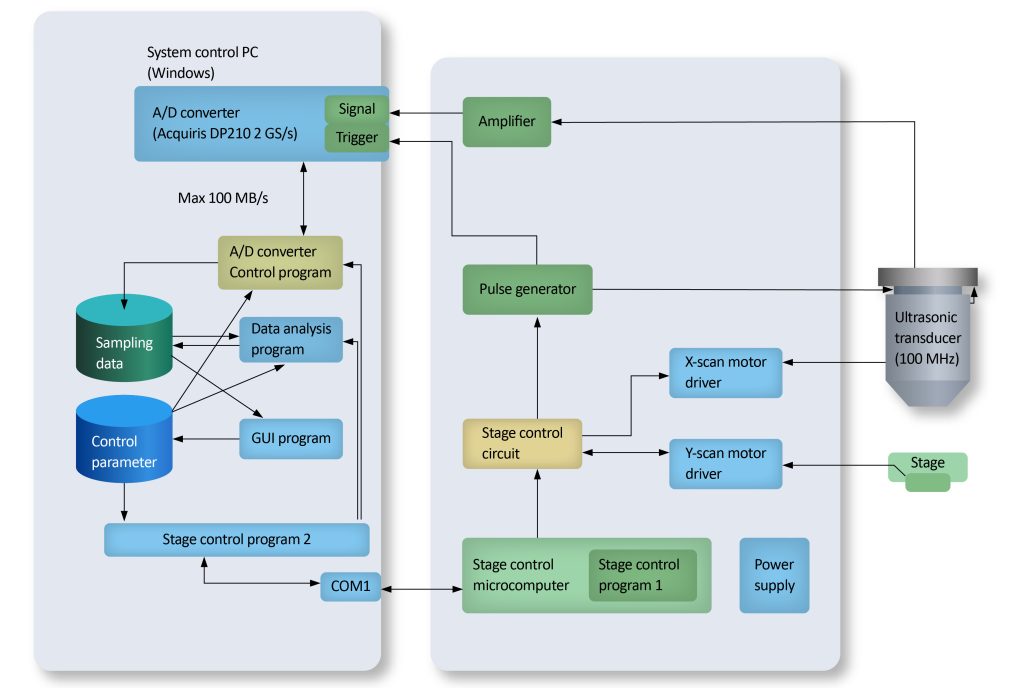

Similar to an optical microscope, an acoustic microscope transmits electrical signals to the transducer through a high-frequency electrical transmitter, and the transducer emits high-frequency sound waves, which are focused on the sample through the acoustic lens, and the ultrasound passes through the sample and reaches the opposite side of the confocal point Acoustic lens, the sound wave with the sample signal is converted into an electrical signal by the transducer and sent to the recording and display device.

An ultrasound microscope, also known as a scanning acoustic microscope (SAM), is a device that uses ultrasound waves to generate high-resolution images of the internal structure of a sample. It is a nondestructive imaging technique commonly used in materials science, biology, and other scientific fields.

The five parts of the acoustic microscope system are:

A typical acoustic microscope system consists of five parts: an acoustic transducer, mechanical scanner, analog signal processor, image signal processor, and display unit.

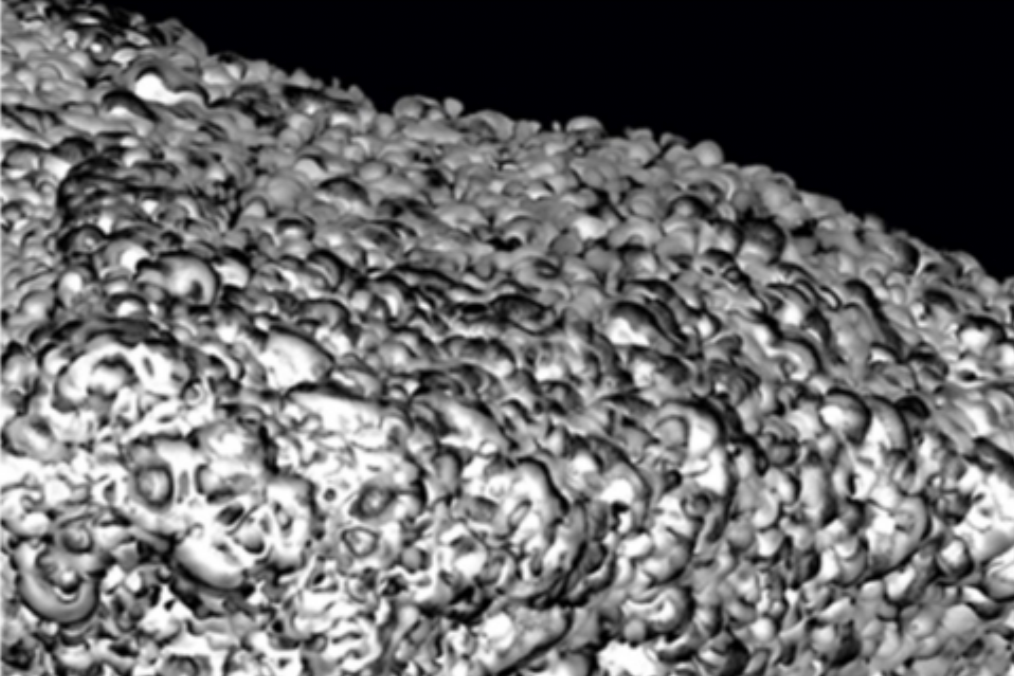

The scanning microscopic method of the ultrasonic microscope can accurately reflect the interaction between the sound wave and the elastic medium of the tiny sample, and analyze the signal fed back from the inside of the sample.

Each pixel on the image corresponds to the signal feedback from a two-dimensional space coordinate point at a certain depth in the sample, and a complete image is formed by scanning the sample point by point and line by line in this way.

The reflected mechanical wave is appended with a positive or negative value so that the time of signal travel can be used to reflect the depth of the sample. A digital waveform on the user’s screen shows the feedback received to select the depth and extent of the sample to be observed.

Working principle of the ultrasonic microscope:

- Ultrasound Generation: The microscope emits high-frequency sound waves (typically in the 1-100 MHz range) toward the sample being examined. These sound waves are generated by piezoelectric transducers, which convert electrical signals into mechanical vibrations.

- Sample interaction: Acoustic waves penetrate the sample and interact with its internal structure. When waves encounter interfaces between different materials or structures in a sample, they are reflected, refracted or scattered.

- Detection: Reflected or scattered sound waves are detected by the same piezoelectric transducer or a separate receiver. The transducer converts the mechanical vibration caused by the return wave back into an electrical signal.

- Signal Processing: Electrical signals are processed and analyzed by the electronics of the microscope. Valuable information can be extracted from the received signal using various techniques such as time gating, phase analysis, or amplitude analysis.

- Image formation: The processed signal is used to generate a two-dimensional image of the sample. This image represents changes in acoustic properties, such as density, compressibility, or acoustic impedance, which can reveal details about the internal structure of the sample.

Features and advantages of ultrasonic microscope

Ultrasonic microscopes, or acoustic microscopes, use very high-frequency ultrasound waves to produce images from inside objects. Therefore, it is a non-destructive imaging technique. Lateral detail resolution reaches that of classical light microscopy, and depth resolution is even better.

- Non-destructive testing

- Highly sensitive to voids and delaminated areas

- Provide depth-specific information

- Ability to analyze planar composite materials

Application field

Ultrasonic microscopes are most effective at the interface between solid or liquid substances and gases and are therefore used in all industrial fields, applications include defect detection, material characterization, quality control, failure analysis, medical imaging semiconductor industry and electronics, etc. In biology and medicine, they are used to visualize the internal structure of tissues, study cellular interactions, and study the mechanical properties of biological samples.