With the rapid development of society, there are more and more types of glass, which can meet the different needs of different occasions. By adjusting the material and process of making glass, the manufacturer can make a big change in the properties of the glass material, making it more stable and durable. The main components of most ordinary glass are sodium silicate and other substances, but the composition of some glass is different from ordinary glass, and quartz glass is one of them.

The difference between quartz and glass

1. Quartz glass

Quartz glass, as the name suggests, is a special glass whose composition only contains silicon dioxide (SiO2), often also called fused quartz.

Due to the small thermal expansion coefficient and high-temperature resistance of quartz glass, it can maintain the stability of its material even in an environment with drastic temperature changes.

Moreover, the chemical properties of quartz glass are extremely stable, and it is a good acid-resistant material. Even if it is an acidic chemical drug with a high concentration, it is not easy to be corroded.

Quartz glass has high compressive strength, but it also has the characteristics of high hardness and brittleness.

2. Glass

Glass is an amorphous inorganic non-metallic material, generally made of various inorganic minerals (such as quartz sand, borax, boric acid, barite, barium carbonate, limestone, feldspar, soda ash, etc.). Its main components are silicon dioxide and other oxides. The chemical composition of ordinary glass is Na2SiO3, CaSiO3, SiO2 or Na2O·CaO·6SiO2, etc. The main component is silicate double salt, which is an amorphous solid with an irregular structure. Widely used in buildings, used for wind and light transmission, belongs to the mixture. There is also colored glass that is mixed with certain metal oxides or salts to show color and tempered glass is made by physical or chemical methods.

Quartz crystal, glass is amorphous.

1. The main components of ordinary glass are sodium silicate, silicon dioxide, and calcium silicate, while the main component of quartz glass is silicon dioxide, which is different.

2. The content of silicon dioxide is different. Quartz glass is made of pure silicon dioxide, with a content of more than 99%. The content of silicon dioxide in ordinary glass is generally 70%-75%, and the other components are alkalis such as sodium oxide and calcium oxide. Metals or alkaline earth metals are used to achieve the purpose of lowering the melting temperature and improving material properties.

3. Quartz is a mineral composed of silicon dioxide, with a chemical formula of SiO2. Pure quartz is colorless and transparent. Due to the presence of trace pigment ions or finely dispersed inclusions, or the presence of color centers, it takes on various colors and reduces transparency. With glass Gloss, the fracture is an oily luster. Hardness 7, no cleavage, shell-like fracture. Specific gravity 2.65. Piezoelectricity.

The characteristics and advantages of quartz glass

Silica is found almost everywhere in nature and makes up almost 1/3 of the mass of the earth’s crust. Quartz glass is a general term used to describe all types of quartz glass, and manufacturers refer to the material as fused silica or fused silica.

Fused quartz is made by melting naturally occurring crystalline silica such as sand or crystal. Production methods include electric melting or flame melting. Afterward, the items will appear transparent, translucent or opaque; making it possible to create a wide variety of products.

Fused silica, commonly known as synthetic fused silica, is produced using high-purity silica sand made from SiCL4. The finished product is clear glass with ultra-high purity and improved optical transmission.

- High-temperature resistance

The softening point temperature of quartz glass is about 1730°C, it can be used at 1100°C for a long time, and the temperature can reach 1450°C for a short time.

corrosion resistance

In addition to hydrofluoric acid, quartz glass hardly reacts with other acids, and its acid resistance is 30 times that of ceramics and 150 times that of stainless steel, especially its chemical stability at high temperatures, which cannot be achieved by any other engineering materials. comparable.

- Good thermal stability

The thermal expansion coefficient of quartz glass is extremely small, and it can withstand severe temperature changes. When quartz glass is heated to about 1100 ° C, it will not burst when placed in room-temperature water.

- Good light transmission performance

Quartz glass has good light transmission performance in the entire spectral band from ultraviolet to infrared, and the visible light transmittance is above 95%, especially in the ultraviolet spectral region, the transmittance can reach more than 80%.

- Good electrical insulation performance

The resistance value of quartz glass is equivalent to 10,000 times that of ordinary glass. It is an excellent electrical insulating material and has good electrical properties even at high temperatures. Due to the above-mentioned excellent physical and chemical properties, quartz glass is widely used in various fields such as electric light sources, semiconductors, optical communications, military industry, metallurgy, building materials, chemistry, machinery, electricity, and environmental protection.

Common applications of quartz glass

- Optics

“Most applications of quartz glass take advantage of its optical properties due to its wide transparency range and excellent light transmission (from ultraviolet to infrared region). Quartz glass is not easily damaged by ultraviolet and high-energy radiation. Light can be used in functionalized The light path passes through quartz glass with minimal distortion. Examples of products with optical applications are prisms, lenses, beam splitters, polarizers, mirrors, and windows.

- Lighting device

“High-purity quartz glass is used in a variety of lamps and lighting systems, such as mercury lamps, halogen lamps, xenon lamps, ultraviolet lamps, and arc and incandescent lamps that provide light sources at high temperatures. These lamps are used in several industries, including food and Sterilization and cleaning equipment in the medical industry and exposure equipment in the semiconductor industry.

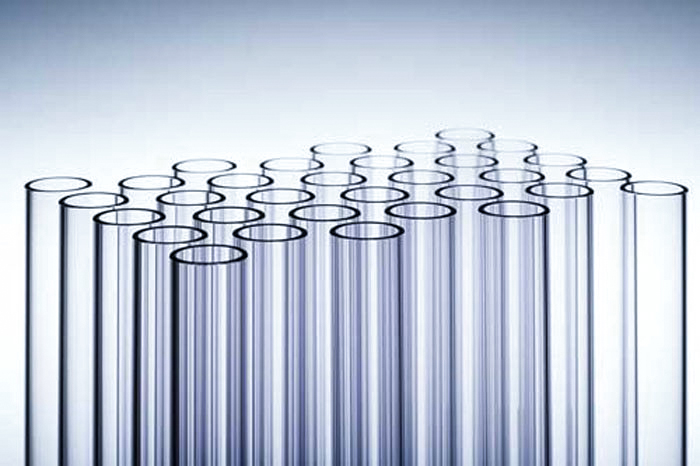

- Chemical equipment and appliances

“Quartz glass material is a good but expensive alternative to other glass types that cannot withstand high-temperature applications for specific uses because it is chemically inert. Common applications are glassware, plates, and tubing.

- Refractory material

“Fused silica is used as a material in the manufacture of refractory parts such as crucibles, trays, shrouds, and drums for high-temperature processes such as steelmaking and glass production.