Powder material

Granular materials generally refer to powders with particle sizes ranging from 0.1 to 1000 microns. Using this as a raw material, through forming and sintering processes, materials and products with the desired shape and excellent performance can be obtained, and no cutting or only a small amount of cutting is required. It is not only widely used in structural components, but also widely used in various functions. components.

Powder is the raw material for the preparation of materials and devices in various fields today, and is widely used in lithium-ion batteries, catalysis, electronic components, medicine and other fields.

The composition and microstructure of the powder raw material determine the performance of the material. The particle size distribution ratio, shape, porosity and specific surface of the powder raw material can match the unique properties of the material.

Therefore, adjusting the microstructure of the raw material powder is a prerequisite for obtaining materials with excellent performance. The specific surface morphology of the powder can be observed by using a scanning electron microscope, and the particle size can be accurately analyzed to optimize the powder preparation process.

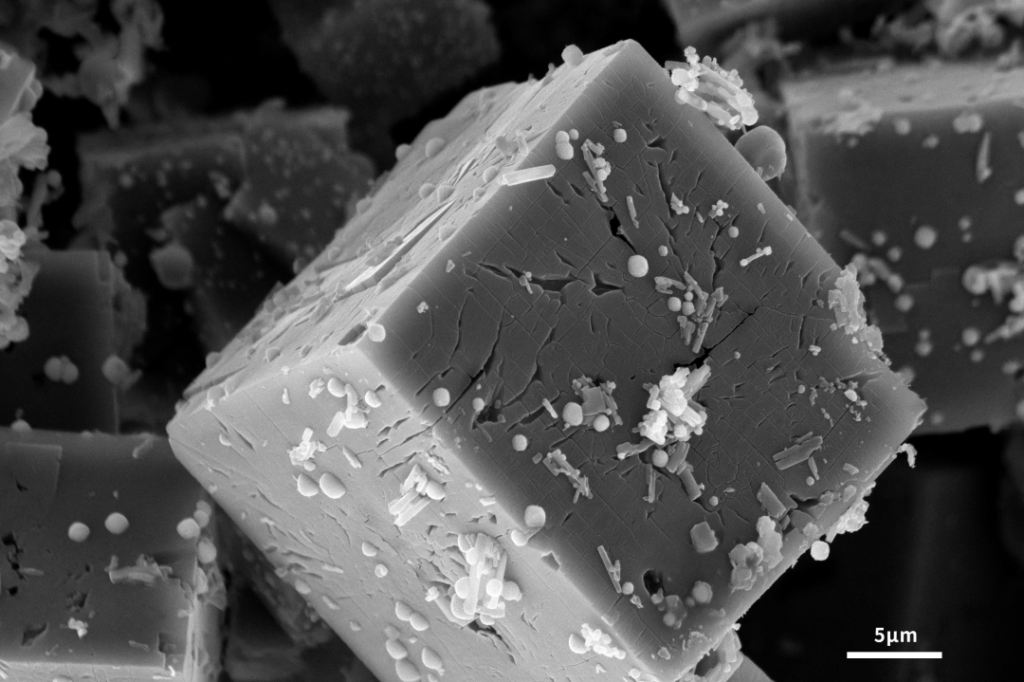

Application of SEM in MOFs Materials

In the field of catalysis, the construction of metal-organic frameworks (MOFs) to greatly improve surface catalytic performance has become one of the current research hotspots. With the unique advantages of high metal loading, porous structure, and catalytic sites, MOFs have great potential as cluster catalysts.

Using a tungsten filament scanning electron microscope, it can be observed that the MOFs material presents a regular cubic shape, and there are fine particles adsorbed on the surface (Figure 1). The electron microscope has a resolution of up to 3nm and excellent imaging quality. It can obtain uniform high-brightness SEM images in different fields of view, and can clearly observe the wrinkles, holes and particle loading on the surface of MOFs materials.

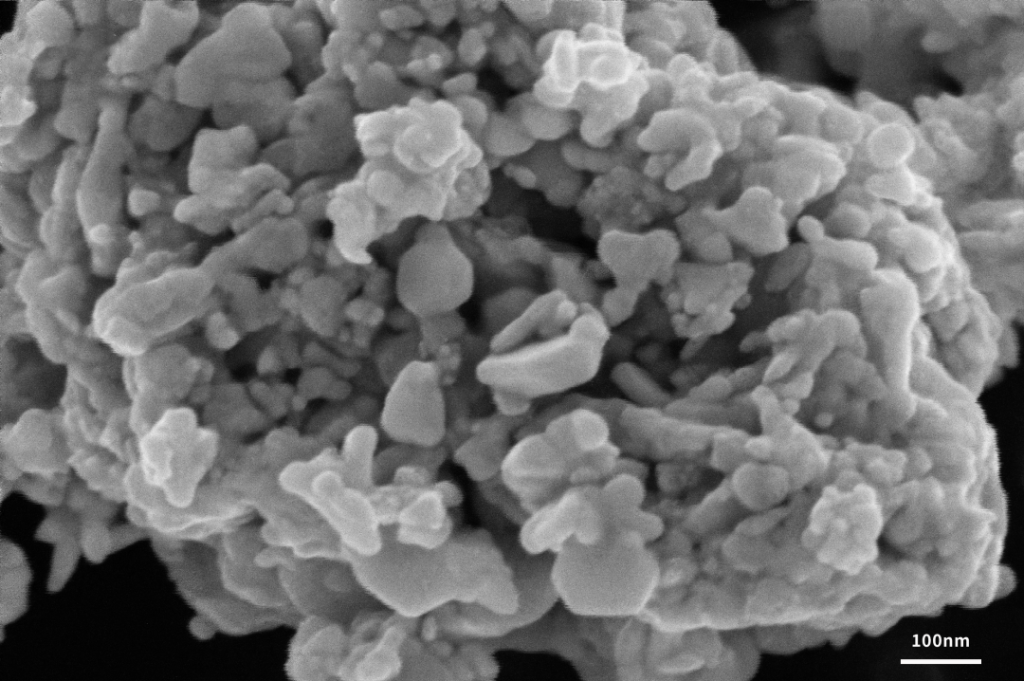

Application of Scanning Electron Microscope in Silver Powder Materials

In the manufacture of electronic components, electronic paste, as the basic material for manufacturing electronic components, has certain rheology and thixotropy, and is a basic functional material integrating materials, chemical industry and electronic technology. The key to conductive paste.

Using SEM5000 field emission scanning electron microscope, relying on high-voltage tunneling technology, the space charge effect is greatly reduced, and irregular silver powders can be observed to agglomerate with each other (Figure 2). And SEM5000 has high resolution, even under 100,000 times magnification, details can still be seen.

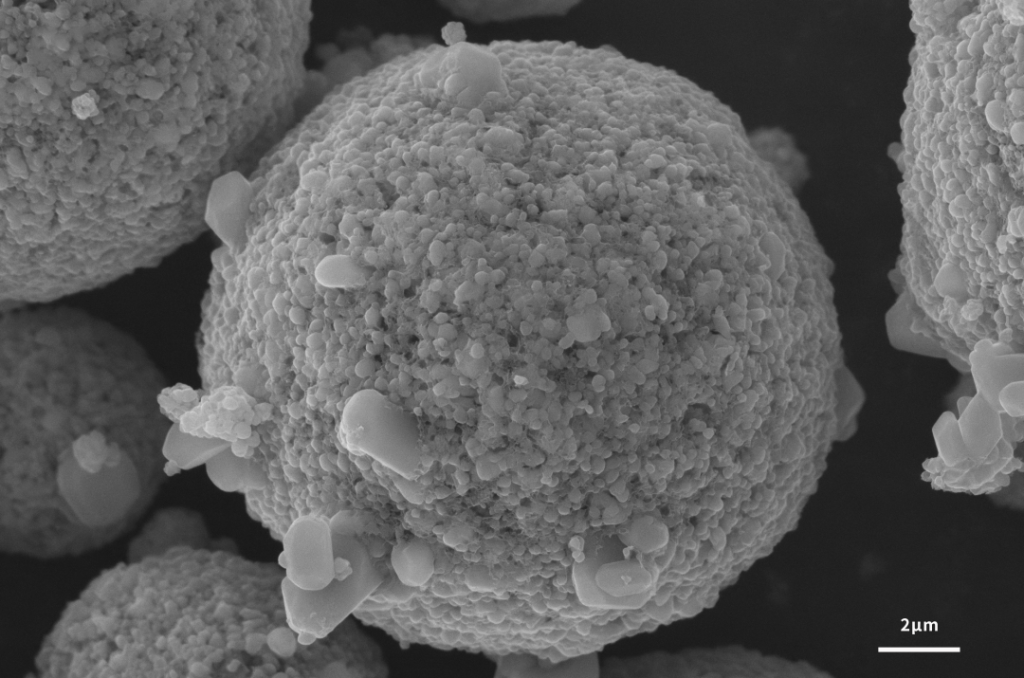

Application of Scanning Electron Microscope in Lithium Iron Phosphate

Lithium-ion batteries quickly occupy the mainstream market because of their advantages such as high specific energy, long cycle life, no memory effect, and high safety. Using an electron microscope to observe the morphology of the positive and negative electrodes of lithium-ion batteries is of great significance for improving the specific capacity of lithium-ion batteries. Among them, lithium iron phosphate batteries are favored due to many advantages such as excellent cycle performance, relatively low price, and guaranteed safety performance.

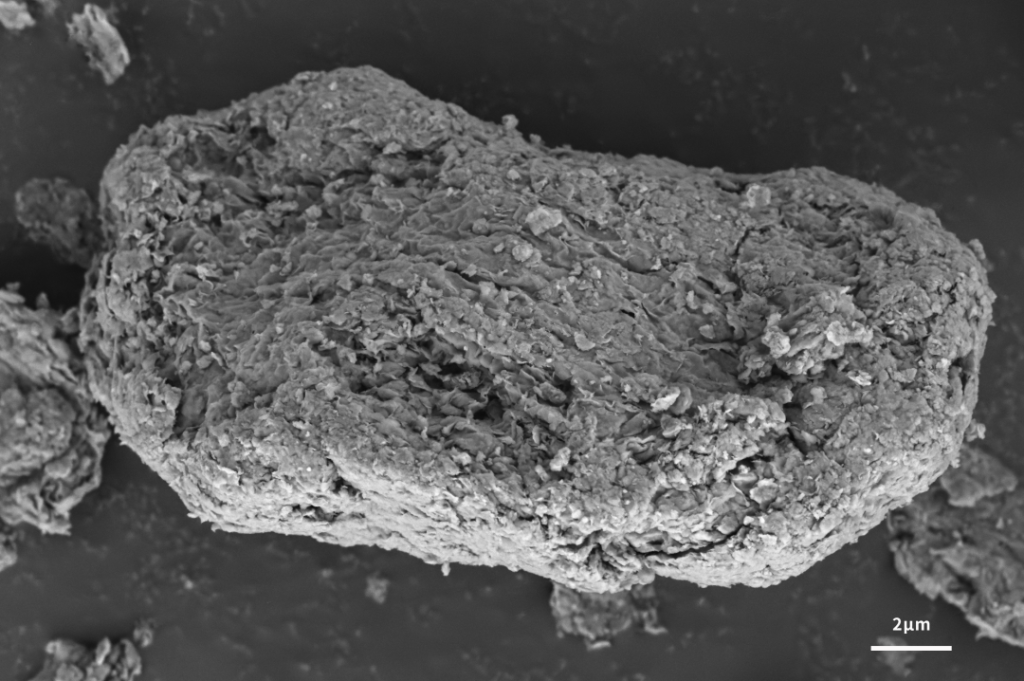

Spherical lithium iron phosphate particles composed of primary particle agglomerations were observed by field emission scanning electron microscope SEM5000 (Figure 3), the surface particles are clear, and the imaging has a three-dimensional sense.

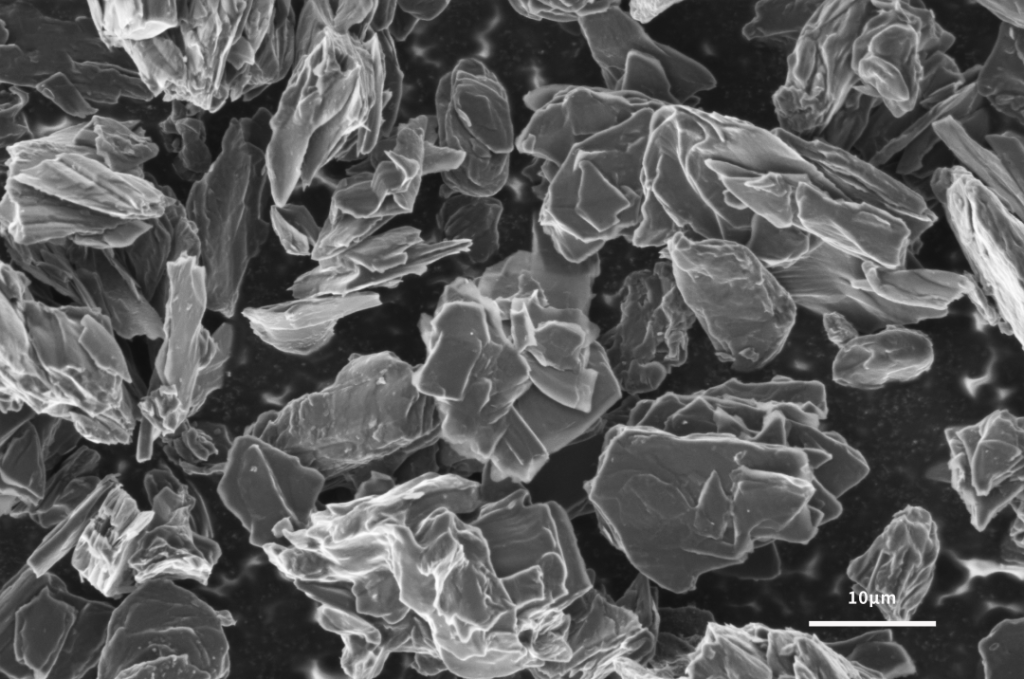

Application of Scanning Electron Microscope in Graphite Materials

The negative electrode material is also one of the core components of lithium-ion batteries, and its structure and properties play a key role in the performance of the battery. Among many carbon-based anode materials, graphite-based materials are the most widely used anode materials commercially.

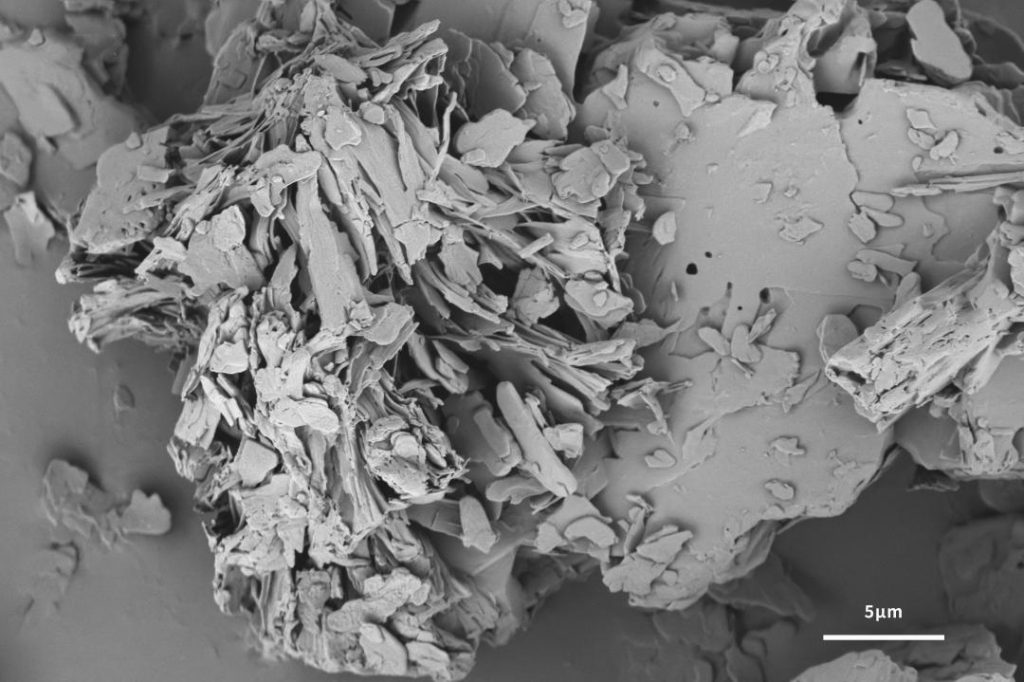

Using a field emission scanning electron microscope SEM3200 tungsten filament scanning electron microscope, it still has excellent imaging quality at low voltage, and can clearly characterize the sheet structure and particle size distribution of the graphite negative electrode (Figure 4).

Application of Scanning Electron Microscope in Smectite Powder

The use of scanning electron microscopy to observe pharmaceutical powders is also indispensable. Among them, montmorillonite powder has a strong fixation and inhibition effect on viruses, germs and the toxins and gases produced in the digestive tract, which can make them lose their pathogenic effects.

SEM5000 field emission scanning electron microscope was used to observe that the surface of montmorillonite has a lamellar structure, and fine lamellar crystal blocks are attached to the surface (Figure 5).

Application of Scanning Electron Microscope in Magnesium Stearate

Medicinal magnesium stearate is an organic compound. It is a white non-sandy fine powder. It has a slippery feeling when in contact with the skin. It is mainly used as a lubricant for tablets. Its advantages are a strong lubricating effect, lightweight and good adhesion.

Field emission scanning electron microscope SEM5000 was used to observe that the magnesium stearate powder was mainly in the form of flakes (Figure 6), and the flakes were related to each other.

Although magnesium stearate is a non-conductive organic substance, it can still image with high resolution in low voltage mode when using Field emission scanning electron microscope SEM5000. It can be seen from the surface morphology that the lubricating texture of magnesium stearate may also be related to the flake structure.

Field Emission Scanning Electron Microscope SEM5000

SEM5000 is a field emission scanning electron microscope with high resolution and abundant functions.

Advanced tube design, high-pressure tunnel technology (SuperTunnel), low aberration and MFL objective design, achieve low voltage high-resolution imaging, and magnetic samples can be applied. Optical navigation, perfect automatic function, carefully designed human-computer interaction, optimized operation and use process, no matter rich experience or not, you can quickly get started and complete high-resolution shooting tasks.