A scanning electron microscope is designed from top to bottom, where an electron beam is emitted by an electron gun. After being focused by a set of condenser Lenses, the size of the electron beam is selected using a condenser aperture. The scanning coil that controls the electron beam is then focused through an objective lens, and a signal receiver is installed on the upper side of the sample, It is used to select Secondary electrons or backscattered electron imaging.

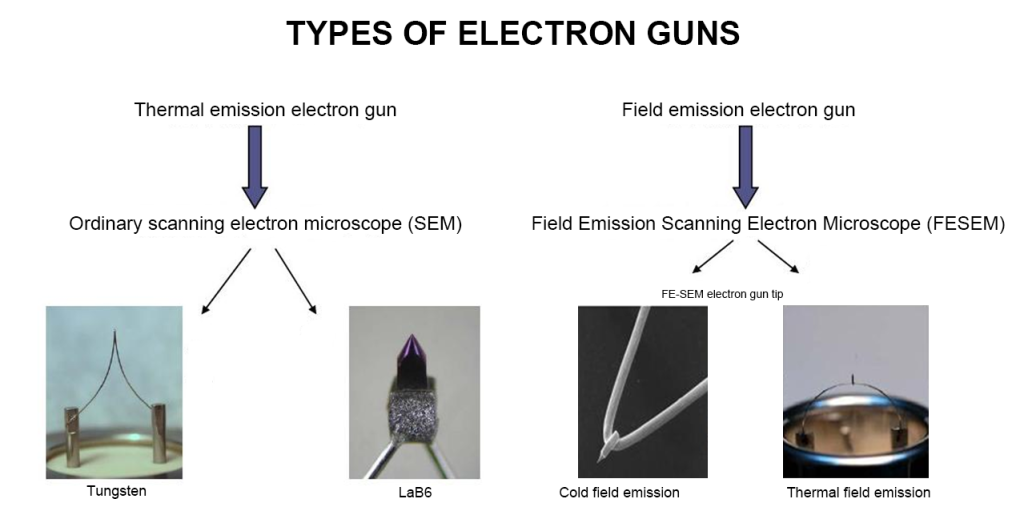

Three types of electron guns:

The necessary characteristics of an electron gun are high brightness and small electron energy spread. Currently, there are three commonly used types, tungsten (W) filament, lanthanum hexaboride (LaB6) filament, and field emission. Different filaments have differences in the size of the electron source, current flow, current stability, and electron source life.

Two thermal emission electron guns:

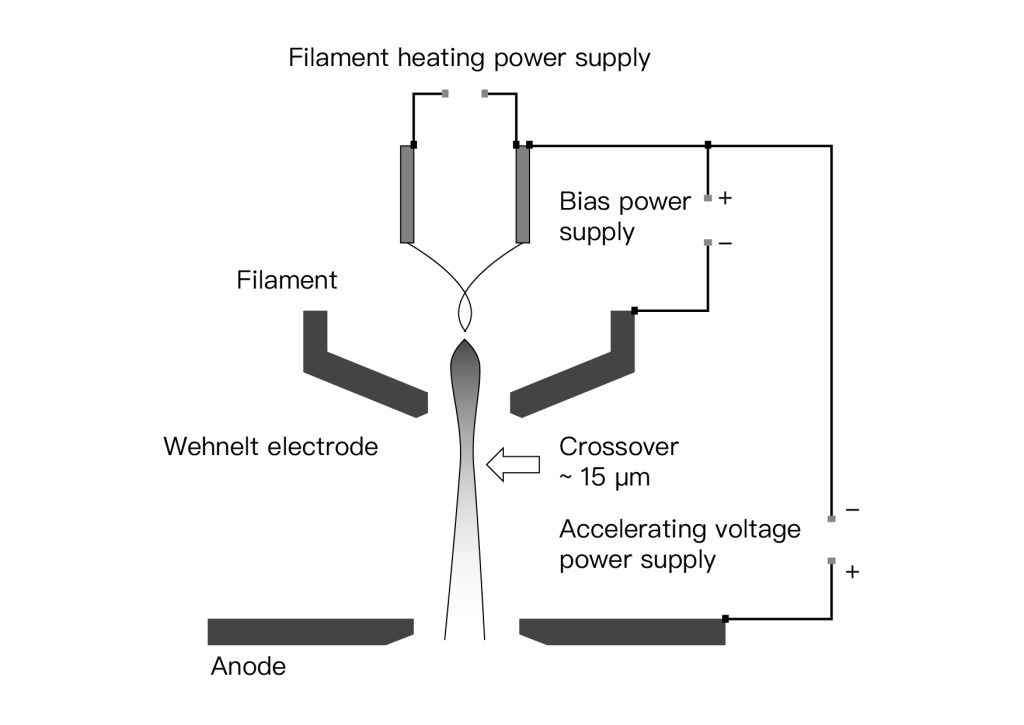

There are two types of thermal ionization electron guns: tungsten (W) filament and lanthanum hexaboride (LaB6) filament. It uses high temperatures to make electrons have enough energy to overcome the work function barrier of the electron gun material and escape. The variables that have a significant impact on the emission current density are temperature and work function. However, when operating the electron gun, it is desirable to operate at the lowest temperature to reduce the volatilization of materials. Therefore, when the operating temperature does not increase, it is necessary to use low-work function materials to increase the emission current density.

The cheapest and most commonly used is the tungsten filament, which emits electrons in the form of thermal dissociation. The energy distribution of the electrons is 2 eV, and the work function of tungsten is about 4.5eV. The tungsten filament is a thin wire with a diameter of about 100µm bent into a V shape. The operating temperature is about 2700K, and the current density is 1.75A/cm2.

The work function of the lanthanum hexaboride (LaB6) filament is 2.4eV, which is lower than that of the tungsten filament. Therefore, the same current density can be achieved by using LaB6 at 1500K, and the brightness is higher. Therefore, the service life is much longer than that of the tungsten filament. The electron energy distribution is 1 eV, which is better than that of the tungsten filament. However, because LaB6 is very active when heated, it must be operated in a good vacuum environment, so the purchase cost of the instrument is relatively high.

Field emission electron guns are 10-100 times brighter than tungsten filaments and lanthanum hexaboride filaments, and the electron energy spread is only 0.2-0.3eV. Therefore, currently commercially available high-resolution scanning electron microscopes all use field emission electron guns, and their resolutions can reach below 1nm.

Common field emission electron guns come in two forms:

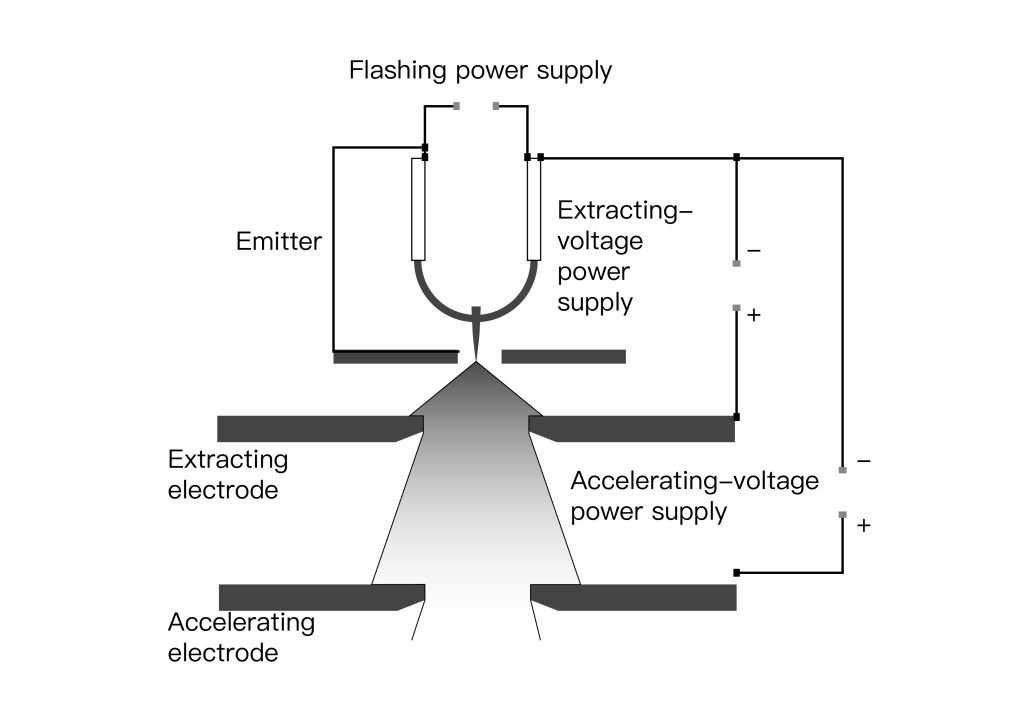

There are two common field emission electron guns: cold field emission (FE) and thermal field emission (TF).

When the metal surface in a vacuum is subjected to an electron-accelerating electric field of 108V/cm, a considerable number of electrons will be emitted. This process is called field emission. The principle is that the high electric field causes the potential barrier of electrons to produce the Schottky effect, that is, the width of the energy barrier becomes narrower and the height becomes lower, so electrons can directly “tunnel” through this narrow energy barrier and leave the cathode.

Field emission electrons are emitted from a very sharp cathode tip, so an extremely thin electron beam with high current density can be obtained, and its brightness can reach hundreds or even thousands of times that of a thermal ionization electron gun.

The cathode material selected for the field emission electron gun must be a high-strength material to withstand the high mechanical stress imposed on the tip of the cathode by a high electric field. Tungsten is a better cathode material because of its high strength. A field emission gun usually has a set of upper and lower anodes to produce functions such as absorbing electrons, focusing, and accelerating electrons.

The electrostatic field generated by the special shape of the anode can produce a focusing effect on the electrons, so there is no need for a Weiss mask or a grid. The first (upper) anode is mainly to change the extraction voltage of the field emission to control the current intensity of the needle tip field emission, and the second (lower) anode is mainly to determine the acceleration voltage to accelerate the electrons to the required energy.

To field-emit electrons from an ultra-fine tungsten tip, the metal surface must be completely clean without any atoms or molecules of foreign materials on the surface. Even if only one foreign atom falls on the surface, it will reduce the field emission of electrons. Therefore, the field emission electron gun must maintain an ultra-high vacuum to prevent the accumulation of atoms on the surface of the tungsten cathode.

Due to the extremely high price of ultra-high vacuum equipment, field emission electron guns are rarely used unless high-resolution SEMs are required. The biggest advantage of the cold field emission type is that the diameter of the electron beam is the smallest and the brightness is the highest, so the image resolution is the best. The energy spread is minimized, which improves the effect of operating at low voltage.

In order to prevent the needle tip from being adsorbed by foreign gas, which will reduce the field emission current and make the emission current unstable, the cold field emission electron gun must be operated under a vacuum of 10-10 torr. Even so, it is necessary to periodically heat the needle tip to 2500K (this process is called flashing) to remove the adsorbed gas atoms. Another disadvantage is that the total current emitted is minimal.

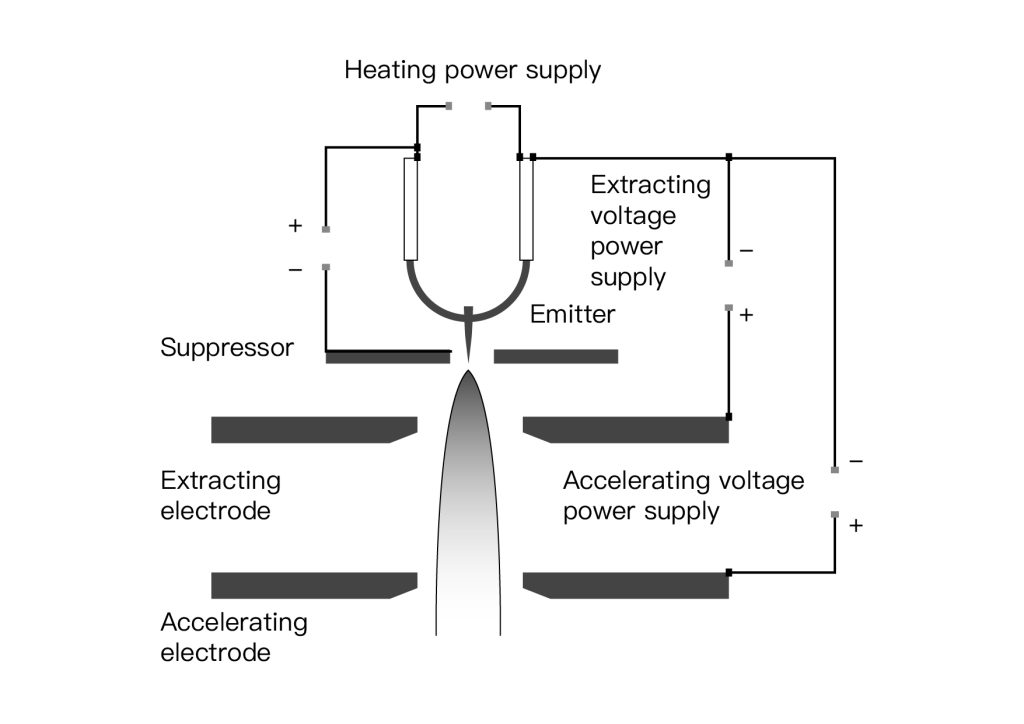

Thermal field emission gun

The so-called thermal field emission gun is a ZrO2/W emitter that uses the Schottky emission principle to emit electrons. here

Several conditions are required:

1. The tip radius of metal tungsten is r≈0.1~1um, and the potential gradient│E│>106V/cm.

2. ZrO2 coating can reduce the work function of metal tungsten from 4.5eV to 2.7eV.

3. Emitter temperature exceeds 1500°C.

When the above conditions are met, electrons will be excited out of the metal surface and enter the vacuum. Thus, a large electron beam current is obtained.

The thermal field electron gun operates at a temperature of 1800K, which avoids the adsorption of most gas molecules on the surface of the needle tip, thus eliminating the need for needle tip flashing. The thermal type can maintain better emission current stability, and can operate under poor vacuum (10-9 torr). Although the brightness is similar to the cold type, its electron energy distribution is 3 to 5 times larger than that of the cold type, and the image resolution is poor, so it is usually used less frequently.