Metallurgical microscope

Metallographic microscopes are suitable for aviation manufacturing, machinery manufacturing, vehicle manufacturing, boiler and pressure vessel manufacturing and inspection, petrochemical industry, railways, shipbuilding, power plants, power stations, equipment installation, large molds, safety testing, quality supervision, physical and chemical laboratories, etc. industry.

Why is the metallographic microscope called metallography:

- 1. Metallography refers to the chemical composition of a metal or alloy and the physical and chemical states of various components inside the alloy.

- 2. A metallographic microscope is generally a microscope with a magnification of less than 1000 times. The one I have used has four magnifications, 50, 100, 150 and 200 times. The magnification is non-continuously adjustable. You can see that the diameter is 10um. Metal particles generally have CCD interfaces.

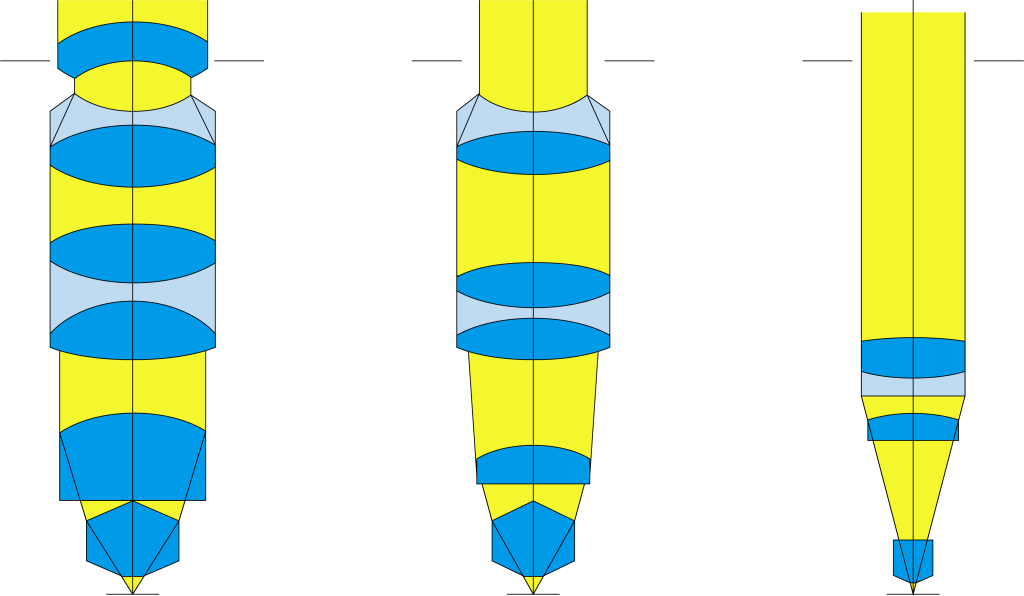

The optical system of a metallographic microscope mainly consists of objective lenses and eyepieces; the illumination system consists of light sources, diaphragms and color filters.

Classification of metallographic microscope objectives

The following mainly introduces the classification of objective lenses

Divided into three categories according to the color difference

- 1 Achromatic objective lens

Achromatic objective lens is a common objective lens. It is composed of several sets of positive and negative cemented lenses with different curvature radii. It can only correct the axial chromatic aberration of red light and blue light in the spectral line, and at the same time correct the on-axis point spherical aberration and Paraxial point coma. This kind of objective lens cannot eliminate the secondary spectrum, and the image field curvature is large. In other words, it can only obtain a clear image in the middle range of the field of view.

This type of objective lens has a simple structure, is economical and practical, and is widely used in mid- and low-level microscopes.

- 2 Semi-apochromatic objective lens

Part of the lens of a semi-apochromatic objective lens is made of fluorite material, so it is also called a fluorite objective lens. Its performance is better than that of an achromatic objective lens, and its price is cheaper than that of an apochromatic objective lens.

- 3 Apochromatic objective lens

Apochromatic objective lens This objective lens corrects the axial chromatic aberration of red, blue and yellow light and eliminates the secondary spectrum, so the image quality is very good.

Because microscopes are first used for observation with the human eye, all current microscope objectives are achromatic. However, since the vast majority of current microscopes are equipped with photographic functions, the flatness of the image field imaged after passing through the objective lens is required to be relatively high, and achromatic aberration alone is not enough. Therefore, among the microscopes commonly used in the world, except for a few, only achromatic Except for stereomicroscopes for human observation, planar objectives are basically used, but on some low-end microscopes, there are also some non-plan achromatic objectives.

Divided into three categories according to the flatness of the image field

Due to the curvature of the field caused by the achromatic objective lens, the image plane is curved. When observing the sample, the image in the middle of the field of view is clear, but the edges are blurred. Just for observation, the user can accept it. First, see the middle image clearly, and then move the edges. By observing in the middle, you can understand the entire image, but this brings inconvenience to the user’s photographic recording. The objective lens designed to have a flat image plane is mainly achieved by using a meniscus-shaped concave and convex thick lens, special optical glass and high-precision production technology, so the cost is high and the price rises.

- 1 Plan achromatic objective lens

Plan achromatic objectives adopt a complex optical structure composed of multiple lenses, which can better correct astigmatism and field curvature. Therefore, the entire field of view can be clear, overcoming the phenomenon of uneven field of view clarity of achromatic objectives, but there is still residual chromatic aberration, that is, the secondary spectrum has not been eliminated. It must be pointed out that if the vertical axis chromatic aberration of plan achromatic is less than 1%, it can be used without compensating eyepieces with excessively positive chromatic aberration. If the vertical axis chromatic aberration is less than 2.5% and greater than 1%, it should be used with plan achromatic. Use with field compensation lens.

- 2 Plan apochromatic objective lens

Although plan apochromatic objectives further correct the secondary spectrum, they still lack correction for vertical axis chromatic aberration, and the image plane curvature is not fundamentally improved compared to general achromatic objectives. Plan apochromatic objective lenses correct astigmatism and curvature of field, as well as axial chromatic aberration of the red, blue, and yellow spectral lines. They are the best form of microscope objectives. The entire field of view is flat, clear, and comfortable for observation.

- 3 Plan semi-apochromatic objective lens

Plan semi-apochromatic objective lenses According to the achromatic situation, there are also plan semi-apochromatic objectives that are between the first two. Generally, because they use fluorite material, they are also called fluorite objectives.

Divided into four categories according to magnification

- 1 Low magnification objective lens

Low magnification objective lens magnification <10 × numerical aperture 0.04~0.15

- 2 Medium magnification objective lens

Medium magnification objective lens magnification ≥10×~50× numerical aperture 0.25~0.85

- 3 High magnification objective lens

High magnification objective lens magnification ≥50×~250× numerical aperture>0.4~0.95

- 4 Oil immersion high magnification objective lens

Oil immersion high-power objective lens, magnification 50×~100×, numerical aperture 0.85~l.32

According to the properties of the medium existing between the objective lens and the sample when observing the sample, it is divided into two categories

- 1 Dry objective lens

The dry objective lens uses an air layer as the medium between the objective lens and the sample.

- 2 Immersion system objective lens

Immersion objective lenses add a certain liquid between the objective lens and the specimen. The commonly used immersion liquid is cedar oil, and some immersion liquids are water. But the metallographic microscope is basically observation under a dry microscope.

Objective lens markings

Different marks are engraved on the objective lens shell, indicating the immersion mark, objective lens type, and magnification. Numerical aperture, mechanical barrel length, cover glass thickness and other information

Nowadays, generally objective lenses are plan objectives, so they are marked PLAN or PL; semi-apochromatic objectives are marked FLUOTAR or FL; apochromatic objectives are marked APO

∞ = infinity correction infinity correction

_/0 = coverglass correction (0.17), corr.(0-2) coverglass correction

A= ICR prism position (B, D, E) differential interference prism position

PL APO= optical quality (Hi Plan, N Plan, Plan Fluotar, Plan Apo) optical properties

L or H= Long Distance, Heating stage long working distance, high temperature stage

50x= Magnification magnification

0.90= numerical aperture numerical aperture

BD= brightfield/darkfield brightfield/darkfield

PH= Phase Contrast

A colored circle engraved on the objective lens indicates the magnification of the objective lens.

According to relevant regulations, the color circles on the surface of commonly used objective lens housings are represented, such as using red, yellow, green, blue, dark blue, and white to mark 5×, 10×, 20×, 50×, 63×, and 100× objective lenses respectively.