As an ancient material, glass can not only be used in the fields of architecture and art, but is also often used in medical treatment and instrumentation. Different types of glass have different characteristics, which must be paid attention to when using them. However, most people don’t know enough about glass, which often causes some misunderstandings and troubles. In this article, we will analyze the different types of optical glass and introduce several coating methods on the glass surface.

There are six different types of optical glass

Colorless optical glass、Anti-radiation optical glass、Radiation resistant optical glass、Colored optical glass、Ultraviolet and infrared optical glass、Optical quartz glass

01 colorless optical glass

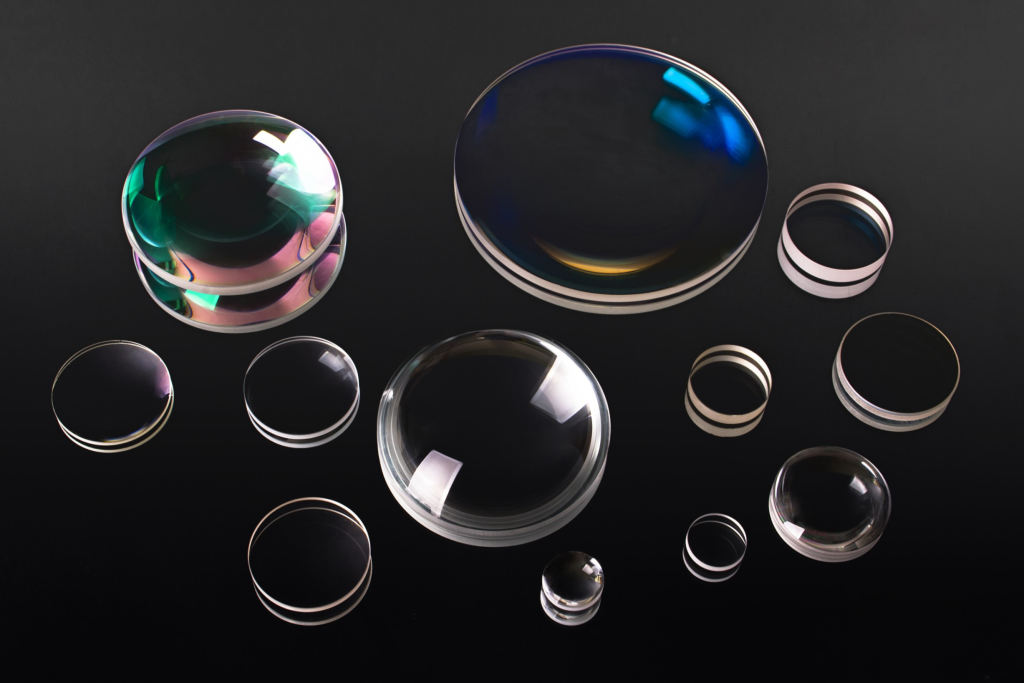

There are specific requirements for optical constants, and it has the characteristics of high transmission in the visible region and no selective absorption and coloring. According to the Abbe number, it is divided into crown type and flint type glass, and each type is divided into several types according to the refractive index, and arranged in order according to the refractive index. It is mostly used as lenses, prisms, mirrors, etc. for telescopes, microscopes, and cameras.

02 Anti-radiation optical glass

It has a greater absorption capacity for high-energy radiation. There are high-lead glass and CaO-B2O2 system glass. The former can prevent γ-ray and X-ray radiation, and the latter can absorb slow neutrons and thermal neutrons. It is mainly used in the nuclear industry. , medical fields, etc. as shielding and peeping window materials.

03 Radiation resistant optical glass

Under certain γ-ray and X-ray irradiation, the transmittance in the visible area changes less, and the variety and grade are the same as those of colorless optical glass. It is used to manufacture optical instruments and peep windows under high-energy irradiation.

04 Colored optical glass

Also known as filter glass. It has selective absorption and transmission properties for specific wavelengths in the ultraviolet, visible, and infrared regions. According to the spectral characteristics, it is divided into three types: selective absorption type, cut-off type and neutral gray; according to the coloring mechanism, it is divided into ion coloring, metal colloid coloring and sulfur selenium. There are three types of compound coloring, mainly used in the manufacture of optical filters.

05 Ultraviolet and infrared optical glass

It has specific optical constants and high transmittance in the ultraviolet or infrared band, and is used as an ultraviolet or infrared optical instrument or as a window material.

06 Optical quartz glass

With silicon dioxide as the main component, it has the characteristics of high temperature resistance, low expansion coefficient, high mechanical strength, and good chemical properties. It is used to manufacture prisms, lenses, windows, and reflectors that have special requirements for transmission of various wavelength bands. In addition, there are photomasks, liquid crystal display panels, and disc-based thin glass used in large-scale integrated circuits; magneto-optical glass in which the polarization plane rotates when light passes through the glass along the direction of magnetic force lines; light passes through the glass in a certain direction Ultrasonic glass, acousto-optic glass that undergoes light diffraction, reflection, convergence, or optical frequency shift.

There are four coating methods on the glass surface

The coating is to coat the surface with a very thin transparent film to reduce light emission. There are many production methods of coated glass, mainly the vacuum magnetron sputtering method, a vacuum evaporation method, the chemical vapor deposition method and the sol-gel method.

1. Magnetron sputtering coating glass can design and manufacture multi-layer complex film systems by using magnetron sputtering technology and can plate a variety of colors on the white glass substrate. The corrosion resistance and wear resistance of the film layer are good, which is the production And one of the more used products.

2. There is a certain gap between the variety and quality of vacuum evaporation-coated glass and magnetron sputtering-coated glass, which has been gradually replaced by the vacuum sputtering method.

3. The chemical vapor deposition method is to pass the reaction gas into the float glass production line to decompose on the hot glass surface, and evenly deposit on the glass surface to form coated glass. The method is characterized by less investment in equipment, easy regulation, low product cost, good chemical stability, and thermal processing. It is one of the more promising production methods.

4. The process of producing coated glass by sol-gel method is simple and stable, but the disadvantage is that the light transmittance of the product is too high and the decoration is poor.