The application of electron microscope technology is based on the optical microscope. The resolution of the optical microscope is 0.2μm, and the resolution of the transmission electron microscope is 0.2nm. That is to say, the transmission electron microscope is magnified 1000 times on the basis of the optical microscope.

Scanning electron microscopy plays an irreplaceable role in the development of modern science and technology. It is not only widely used in academic research, but also has great significance in industrial manufacturing, medical testing, environmental monitoring and other fields.

An electron microscope consists of three parts: lens barrel, vacuum device and power supply cabinet.

The lens barrel mainly includes components such as electron source, electron lens, sample holder, fluorescent screen and detector, and these components are usually assembled into a cylinder from top to bottom.

The electron microscope electron gun is a component that generates an electron beam with a certain energy and is composed of a cathode (filament), a grid and an anode.

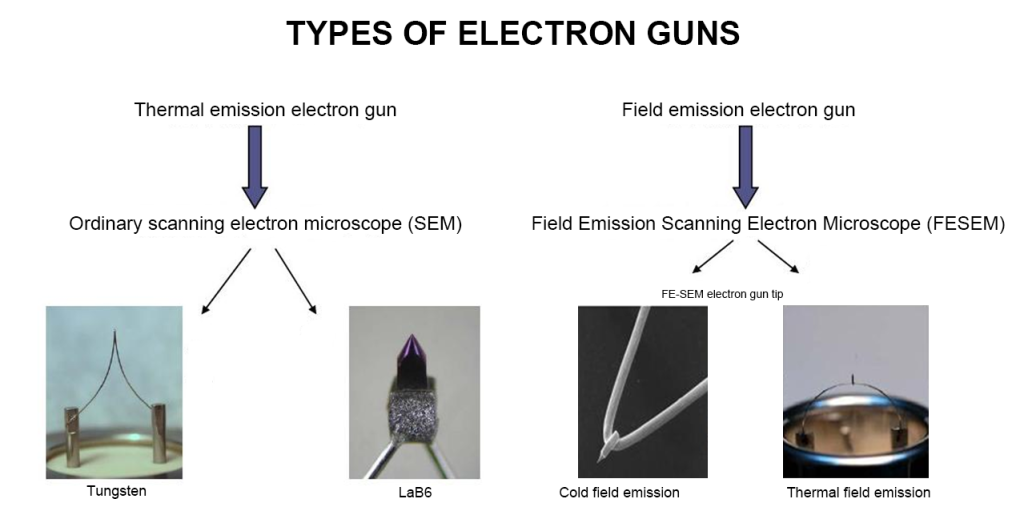

There are three main types of filaments: tungsten filament, LaB6 and field emission.

In the scanning electron microscope, the tungsten filament electron microscope has many similarities with the field emission electron microscope. All are equipped with an electron gun, that is, a device that emits electrons, has a cathode and an anode, and the cathode is a point source emission. However, the difference between the two is also very worthy of your attention. This paper introduces the differences between the two from four aspects: point source diameter, emission mechanism, electron gun control method, electron source diameter, and system vacuum.

1. The diameter of the point source is different

The cathode of the tungsten filament electron gun uses a 0.1mm diameter tungsten wire to make a V-shape (fork-type tungsten wire cathode), using the V-shaped tip as a point emission source, and the radius of curvature is about 0.1mm;

The cathode of the field emission electron gun uses a tungsten wire with a diameter of 0.1mm, which is corroded to make a needle-shaped pointed cathode, and the general radius of curvature is between 100nm and 1μm. Due to the difference in the manufacturing process, the cost is different, the fork-type tungsten wire cathode is cheap, and the field emission cathode is very expensive.

2. The launch mechanism is different

The tungsten filament belongs to thermal emission. When DC voltage is applied to the filament electrode, the tungsten filament will generate heat. The operating temperature is generally between 2600K and 2800K. The tungsten filament has a high electron emission efficiency. The higher the temperature, the greater the current density, and the higher the brightness of the electron gun under ideal conditions. Since the evaporation rate of the material increases sharply with the increase of temperature, the life of the tungsten filament is relatively short, generally between 50 and 200 hours, which is related to the set filament temperature. Due to the high electron emission temperature, the energy dispersion of the emitted electrons is large, generally 2ev, and the chromatic aberration caused by the electron gun will be relatively large.

The main emission mechanism of the field emission electron gun is not to heat the cathode, but to increase a strong electric field on the surface of the sharp cathode, thereby reducing the surface barrier of the cathode material, and can narrow the surface barrier width to the nanometer scale, thereby appearing quantum tunneling effect.

3. Electron gun control method and electron source diameter

The tungsten filament is controlled by a three-pole self-sufficient bias voltage and has a bias negative feedback circuit, so the stability of the emission current is high; due to the large area of the cathode emission point source, the size of the electron source is also relatively large, 50-100 μm, and the emission can reach tens to 150 μA, but the brightness of the electron gun is low. Therefore, when the electron beam spot is focused to a few nanometers, the total probe current is very small.

The field emission electron gun has no bias negative feedback circuit, the stability of the external power supply is the decisive factor, and the stability of the emission current is lower than that of the tungsten filament lamp. Since the emission power area of the pointed cathode is very small, about 100nm, there is no obvious electron source, so the virtual electron source is used as the initial object for the design of the electron optical system. The diameter of the electron virtual source is generally 2~20nm, and the brightness of the electron gun is thousands of times higher than that of the tungsten filament. When the beam spot size is reduced to less than 1nm, it still has a strong enough probe current to obtain sufficient imaging signals, so the resolution is high, and the current best field emission scanning electron microscope has achieved sub-nanometer resolution.

4. The vacuum degree of the system is different

The tungsten filament scanning electron microscope uses a general high vacuum, and the vacuum degree of 0.001pa can be satisfied by the two-stage vacuum pump system, so the cost is low.

The field emission scanning electron microscope uses ultra-high vacuum, and the three-stage vacuum pump must obtain a vacuum degree above 0.0000001Pa to work stably.

The reason for this difference is that:

(1) The cathode of the electron gun tip is not resistant to being bombarded by ionized ions in a lower vacuum, otherwise the gun tip is easily swept away and fails, and the performance at this time is not as good as that of the tungsten filament.

(2) When the cathode tip of the electron gun is in a low vacuum, the adsorbed gas molecules will sharply increase the surface barrier of the cathode material, resulting in unstable emission of the electron gun and reduced brightness. Therefore, ultra-high vacuum must be used, generally 10-8.

(3) The cost of the ultra-high vacuum system is obviously much higher than that of the tungsten filament. The cleanliness of ultra-high vacuum is better than the general high vacuum of tungsten filament, so the system can be free of cleaning and maintenance for a long time, that is, within the life of the filament. Tungsten filament scanning electron microscopes have relatively shorter maintenance cycles.