Experiments have shown that there are unexpected obstacles to achieving better resolution in electron microscopes.

In the past decade, the resolution of electron microscopes has continuously improved, making unprecedented progress. In order to focus electrons, these microscopes use circular electromagnetic lenses, which, unlike glass lenses in optical microscopes, have spherical aberrations.

Therefore, electrons traveling at a larger angle away from the direction of the incident beam focus more strongly than electrons traveling at a smaller angle, thus blurring the image. Although the wavelength of the electrons used is very small, usually within the range of 0.02-0.037 Å, due to limited spherical aberration, it has been impossible for many years to approach the theoretical wavelength limiting resolution. A common analogy is that using an imperfect electron microscope lens to capture images is like trying to see through a glass milk bottle.

For many years, it has been known that the method of manufacturing negative spherical aberration magnetic lenses is to break symmetry and use multipole lenses; For circular lenses, the magnetic field lines are largely parallel to the direction of the electron beam, while in multiple lenses, they are perpendicular to the direction of the electron beam. However, this involves simultaneously controlling a large number of different lens components, which proved difficult before introducing computer control. Shortly thereafter, a design solution to the next major problem emerged, namely color difference (focal length depends on wavelength), which was quickly implemented in commercial machines.

It seems that electron microscopes are on the path of continuously improving resolution, and there are no foreseeable obstacles to achieving better performance. Alas, this seems too optimistic. In Physical Review Letters, Stephan Uhlemann and colleagues from Corrected Electron Optical Systems GmbH (CEOS) in Germany reported an unexpected resolution limitation, namely magnetic noise caused by thermal activation of current or spin in metal components. Because the optical path of the electron in the aberration correction instrument is longer, the electron is sensitive to a very small magnetic field. The author estimates that its order of magnitude is 0.1 nm Tesla, about 100000 times smaller than the earth’s magnetic field.

The experiment conducted by Stephan Uhlemann and colleagues involved modifying the electron microscope by removing the aberration corrector and replacing it with a cooling tube, and then placing different tubes inside (using stainless steel and permalloy materials). Then, they checked how the resolution depends on the inner tube material and temperature and showed significant improvement at lower temperatures, consistent with thermal magnetic noise.

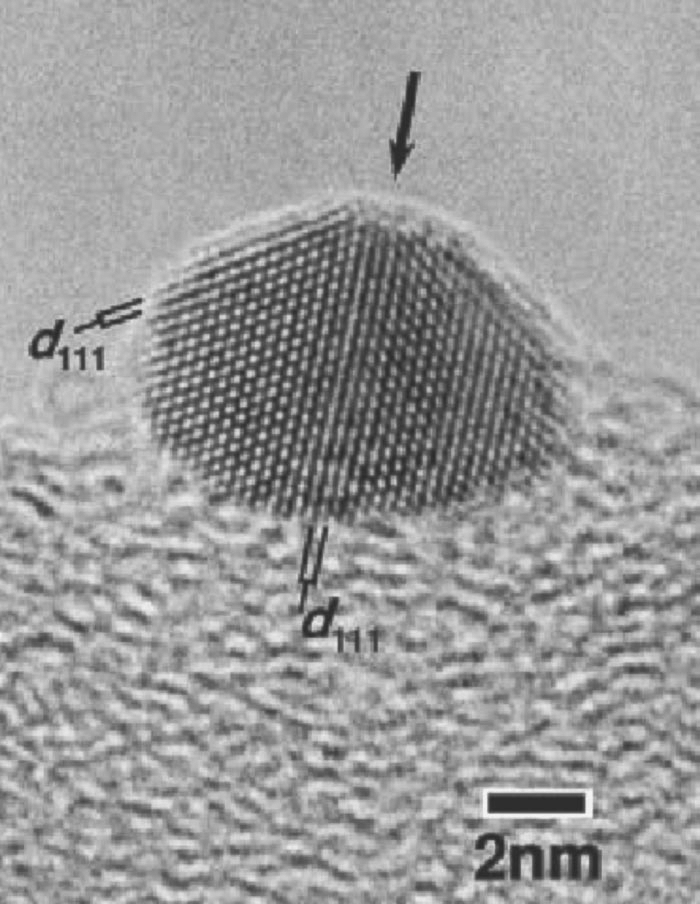

Any Transmission electron microscopy contains many metal parts. Most of these components are structural, but other components transport current to the lens, participate in magnetic field transmission or are used to select which parts of the electron beam participate in the aperture of the final image or spectrum. Typically, these are heterogeneous alloys that contain precipitates, dislocations, grain boundaries, and other phases chosen to improve mechanical and electrical properties or simply reduce costs. In any given time instance, the current/spin may have local fluctuations (the so-called Johnson–Nyquist noise), as shown in Figure 1, which will lead to fluctuations in the magnetic field in sensitive magnetic equipment.

Although the time average effect of these fields is small, fast electrons in the microscope travel at about half the speed of light, so they may be deflected by an instantaneous magnetic field. The average time of many electrons that make up the final image will reduce the coherence of the electron beam, thereby reducing resolution. The author estimates that the resulting resolution is limited within the range of 0.5 to 0.8 Å, which is consistent with the best results achieved so far.

Of course, it is a lofty goal to increase the resolution to 0.1Å, but considering the increasing cost of Transmission electron microscopy, the effectiveness of this is still unclear. Unless the focus is on very thin and relatively simple samples, improving the resolution of the microscope may make the image clearer, but there are also drawbacks.

The Nyquist–Shannon sampling theorem is inevitable. It requires that the effective distance between pixels in the image is four times or smaller than the resolution. Therefore, every time the resolution is doubled, the electron flux/dose needs to be increased by four times, resulting in more beam damage.

At higher resolutions, nonlinear imaging contribution, multiple or dynamic electron diffraction and Inelastic scattering effects will not disappear. For example, although relatively high voltages are used, even a single gold atom can scatter electrons multiple times.

Therefore, even with the use of state-of-the-art microscopes, people must always be wary of overly simplistic explanations. So far, no one has been able to construct a “dynamic diffraction corrector,” and the most important corrector, the “user explained corrector,” is not within sight.

In many ways, the real reward for improving microscope performance is a better signal-to-noise ratio; Increasing the resolution from (for example) 0.8 Å to 0.4 Å has doubled the ability to detect features. In fact, many of the recent achievements of aberration correction microscopes can be attributed to better signal-to-noise ratios..

So, where are we going next?

One method is to reduce the distance of electrons exposed to magnetic noise by increasing the intensity of the magnetic field, in order to achieve the same lens effect.

Another method is to try to find different materials for the electrode and liner; There are about a hundred different types of stainless steel, all of which have slightly different characteristics, and from a cost perspective, high-purity single crystals are not unreasonable.

Of course, it is possible to lower the temperature of the entire instrument to the temperature of liquid helium, but apart from demonstration experiments, this is unlikely to be practical, of course, in conventional laboratory environments.

Now we will wait and see. As solutions to fundamental engineering problems designed to reduce noise sensitivity in Electron optics come under attack, we will see the pace of improvement slow down.