Ⅰ Application of Metallographic Microscope in Measuring Micron-level Film Thickness

Coating the surface of materials is a common practice in various fields such as mechanical engineering, electronics, instrumentation, weaponry, agricultural machinery, hardware, construction, shipbuilding, aerospace, etc., aiming to impart certain properties to materials that they inherently lack, thus improving efficiency or expanding their range of applications. These coating processes generally include electroplating, chemical plating, immersion plating, chemical and electrochemical conversion, as well as painting. Regardless of the coating process used, film thickness is the most basic structural parameter. Therefore, various instruments have been developed, such as electrochemical coating thickness gauges, X-ray fluorescence thickness gauges, etc.

Metallographic microscopes are primarily used for the phase structure analysis of metals. They can also be utilized for thickness measurement of film layers using various planar analysis systems, with high precision, with a minimum error of approximately ±0.8μm, making them suitable for arbitrating measurements of metal coatings and oxide film layers. The focal plane of a metallographic microscope can also be used for thickness measurement of various coating layers, providing accuracy comparable to electromagnetic/eddy current thickness gauges at the micron level.

Ⅱ Principles of Measuring Micron-level Film Thickness Using Metallographic Microscope

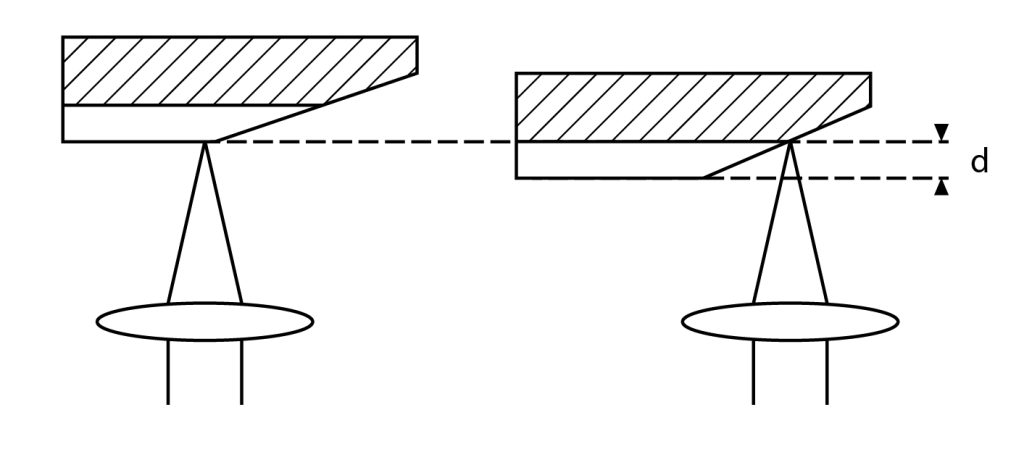

The objective lens focal length and position of a metallographic microscope are fixed. In practical operation, focusing can be achieved by adjusting the height of the sample stage to change the distance between the surface of the sample and the objective lens. After grinding a slope on the coated surface of the object to be tested and placing it flat on the sample stage, the slope should be positioned within the field of view. The focus should be separately adjusted for the outer and inner surfaces of the film layer, and the height difference between the two feet on the focusing knob should be read as the thickness of the film layer.

Ⅲ To relatively accurately measure the thickness of the film layer, attention should be paid to several operational techniques:

- Identify the inner surface of the film layer for focusing, which should exhibit distinct color differences or differences in microstructure.

- The depth of field and magnification of the microscope are inversely proportional. To improve focusing accuracy, the microscope’s magnification should be increased as much as possible to reduce the depth of field.

- When grinding the slope, strive to improve processing accuracy to avoid minor scratches affecting focusing accuracy. Additionally, within the limits of the field of view, minimize the angle between the slope and the surface to increase the visible area of the film layer, thus enhancing focusing accuracy for observation.

- The sample serving as the substrate should have a certain thickness and rigidity to ensure that excessive sample stress deformation does not occur during the slope processing, affecting the original flatness of the sample.

The following three pictures are used as examples, using a metallographic microscope to photograph aluminum-based anodized film samples. The magnification is 450 times, and the angle between the photographing bevel and the sample is about 30 degrees. Photos are shown below:

Ⅳ Experiment and Results of Measuring Micron-level Film Thickness Using Metallographic Microscope

To determine the accuracy of measuring film thickness using the focal plane, a pure aluminum sheet with a nominal thickness of 1mm was used for comparative measurement. Initially, it was vertically fixed on the sample stage, and the software provided with the metallographic microscope was used to select 5 points for measurement randomly. Then, the edge of the aluminum sheet was ground into a slope, and five points within a 5mm length perpendicular to the thickness direction of the aluminum sheet were randomly selected for focal plane height measurement.

| Measuring point | 1 | 2 | 3 | 4 | 5 | Average value |

| Software | 1000.6382 | 1001.1279 | 999.2783 | 999.9738 | 1000.1842 | 1000.2405 |

| Focal plane height | 1001.4 | 1002.6 | 1000.5 | 1001.8 | 998.7 | 1001.0 |

The results showed that using the metallographic microscope for measuring film thickness using the focal plane is feasible and reliable, with reading errors generally less than 1μm.

Ⅴ Conclusion

Measuring various coating thicknesses using the focal plane of a metallographic microscope is feasible and reliable. By grinding the sample coating into a slope and focusing on both interfaces of the film layer separately, the height difference between the two feet of the focusing knob can be read as the film layer thickness. This method is suitable for measuring experimental samples of small size. Compared with other thickness measurement methods, this method allows simultaneous observation and analysis of the microscopic results of the film layer during thickness measurement and is suitable for measuring the thickness of various coating layers or multilayer composite films, without limitations on the properties and morphology of the film layer.