I. What is an Inverted Metallurgical Microscope?

The inverted metallurgical microscope is a type of metallurgical microscope, often categorized into various subtypes such as inverted polarizing metallurgical microscope, inverted differential interference contrast metallurgical microscope, inverted differential metallurgical microscope, and inverted dark-field metallurgical microscope. The term “inverted” in an inverted metallurgical microscope refers to the positioning relationship between the working stage and the objective lens. Typically, a metallurgical microscope with the objective lens positioned below the working stage can be termed an inverted metallurgical microscope.

II. Structural Advantages of Inverted Metallurgical Microscope

The inverted structure confers numerous advantages to the inverted metallurgical microscope. With the lens positioned beneath the working stage, there’s no need to consider the flatness of the non-observed surface of the object during microscopic observation. Additionally, the open space above the inverted stage eliminates concerns regarding the height or size of the observed sample. These distinct advantages make the inverted metallurgical microscope widely applicable in the study of metal materials or other solid block objects.

III. Applications of Inverted Metallurgical Microscope

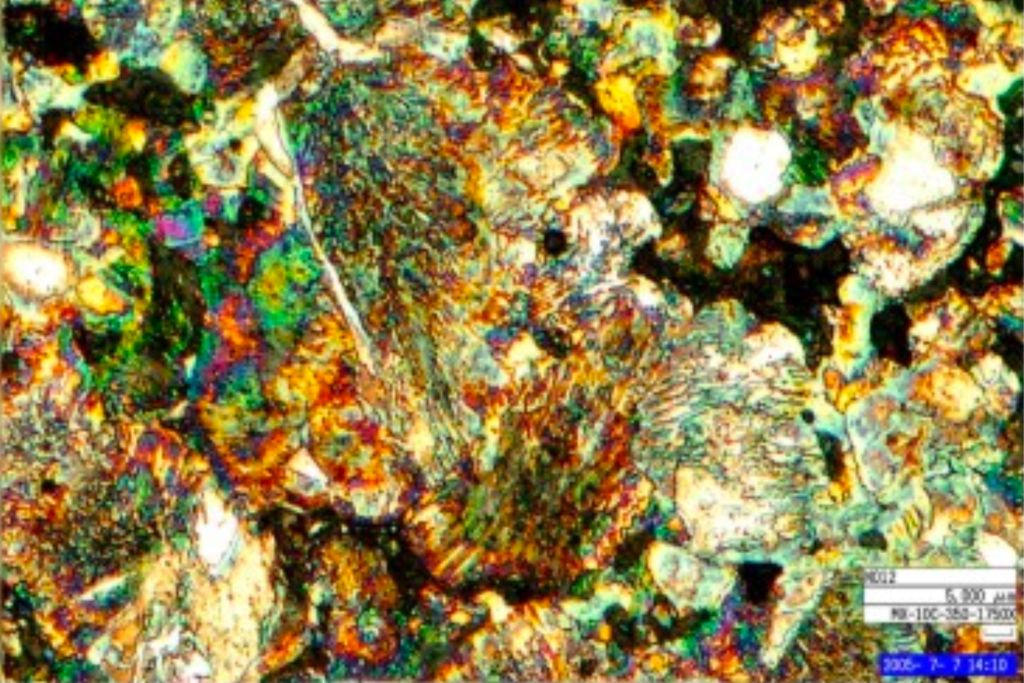

With industrial development, the inverted metallurgical microscope finds extensive applications in the electronics, chemical, and instrumentation industries. It is utilized for observing surface phenomena of opaque materials and conducting research and analysis. Applications include examining chips, printed circuit boards, LCD panels, wires, fibers, coatings, and other non-metallic materials to study and analyze surface conditions.

IV. MR2100 Series Inverted Metallurgical Microscope

The MR2100 series inverted metallurgical microscope is extensively employed in schools, industrial, and mining enterprise laboratories. It is used for identifying and analyzing the structure of various metals and alloys, as well as conducting general metallographic studies of materials post-heat treatment. The microscope offers high imaging clarity compared to similar products, a wide field of view, a stable and reliable structure, and an overall design conforming to human-machine functionality, suitable for prolonged operation.

V. Performance of MR2100 Series Inverted Metallurgical Microscope

- They are designed for teaching, experiments, and routine testing purposes.

- Simple and user-friendly operation with excellent imaging quality.

VI. Technical Specifications of MR2100 Series Inverted Metallurgical Microscope

| Optical system | Finite distance optical system |

| Large field eyepiece | WF10X/18 |

| WF12.5X/14 | |

| WF16X/11 | |

| Achromatic objective lens | Achromatic objective lens 10X/0.25 WD=6.3mm |

| Plan achromatic objective lens 40X/0.65 WD=0.7mm | |

| Plan achromatic objective lens 50X/0.75 WD=2mm | |

| Achromatic objective lens 100X/1.25 (oil) WD=0.1mm | |

| Observation head | Flat-pull binocular observation head |

| Monocular observation head | |

| Built-in digital binocular observation head (200M) | |

| Built-in digital binocular observation head (300M) | |

| lighting | 12V/20W halogen lamp, center and brightness continuously adjustable |

| Focusing mechanism | Coaxial coarse and fine focusing mechanism, fine adjustment scale value 0.002mm, stroke (from the focus point on the stage surface): 8mm |

| converter | Three-hole converter |

| Stage | Mechanical platform 180X155mm, moving range 40X30mm, one platform press, small platform: drop-shaped, round hole |

| filter | Green, yellow, color temperature film |